Rotary Screw Air Compressor For Construction Sites

News 2025-10-24

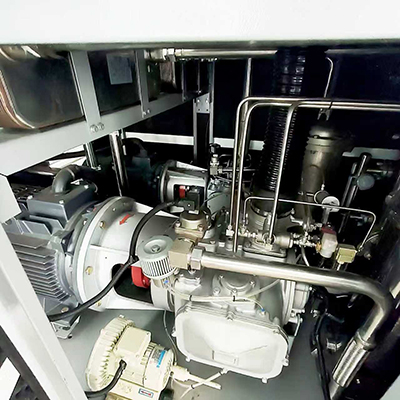

Rotary screw air compressors are a cornerstone of the construction industry, prized for their dependable operation and ability to handle rigorous demands. These devices use two interlocking screws to compress air continuously, providing a steady flow that supports various tools and machinery on site. This technology stands out for its efficiency in energy use and reduced noise levels compared to older compressor types, making it well-suited for both urban and remote construction projects where space and sound constraints are common.

Diverse Applications on Construction Sites

On construction sites, rotary screw air compressors drive essential equipment like pneumatic hammers, drills, and sandblasters, ensuring consistent power for breaking concrete or preparing surfaces. They also facilitate operations such as painting, dust suppression, and operating lifts, where reliable air pressure enhances worker safety and task efficiency. This adaptability allows them to serve multiple roles, from small-scale renovations to large infrastructure projects, streamlining workflows and minimizing equipment needs.

Superior Performance Features

Rotary screw air compressors excel in performance through their high efficiency and durability. Designed for continuous use, they maintain optimal output without frequent stops, which is critical during extended shifts on construction jobs. Their compact build reduces vibration and wear, extending lifespan and cutting maintenance costs, while advanced cooling systems prevent overheating in harsh conditions, supporting sustained productivity and lower energy consumption over time.

Critical Role in Industrial Operations

In industrial contexts, particularly construction, these compressors are vital for maintaining seamless processes and upholding safety standards. They supply clean, dry air that protects sensitive tools from corrosion and ensures precise control in tasks like riveting or material conveyance. By integrating into automated systems, they boost overall site efficiency, help meet tight deadlines, and reduce accident risks, underscoring their importance in achieving high-quality results in modern building practices.