Rotary Screw Air Compressor For Mining Operations

News 2025-10-24

Rotary screw air compressors are essential equipment in the mining sector, designed to handle the rigorous demands of extracting minerals and resources. These machines operate by using interlocking helical screws to compress air continuously, delivering a reliable stream of high-pressure air that powers various tools and systems. In mining environments, where conditions include heavy dust, high humidity, and extreme temperatures, these compressors provide consistent performance, ensuring that operations remain efficient and uninterrupted. Their ability to produce oil-free or lubricated air makes them versatile for applications requiring clean air supply, thus supporting both productivity and safety standards in the industry.

Applications in Mining

Rotary screw air compressors play a critical role in several key areas of mining operations. They are extensively used in drilling activities, where they supply the necessary air pressure to drive pneumatic drills and hammers, allowing for precise and efficient rock breaking. In underground mining, these compressors facilitate ventilation systems by pushing fresh air into tunnels to dilute harmful gases and dust, thereby maintaining a safer working environment. Additionally, they power conveyor belts and other material handling equipment, streamlining the transport of ores and reducing manual labor, which enhances overall operational flow and minimizes downtime.

Performance Advantages

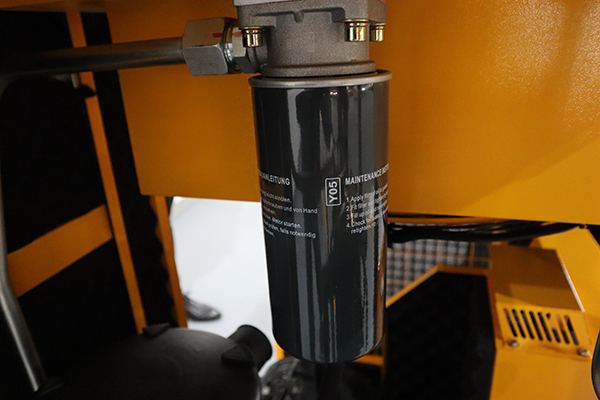

One of the standout features of rotary screw air compressors is their superior efficiency, achieved through minimal energy loss during the compression process. This results in lower operating costs and reduced environmental impact, as they consume less power compared to alternative compressor types. Their design ensures a steady output of compressed air with minimal pulsation, which protects sensitive equipment from damage and extends its lifespan. Furthermore, these compressors are built for durability, with components that withstand abrasive conditions, and they require less frequent maintenance, making them a practical choice for the high-intensity demands of mining.

Importance in Industrial Processes

In the context of industrial mining processes, rotary screw air compressors significantly contribute to enhanced productivity and worker safety. By providing a dependable source of compressed air, they enable the seamless operation of machinery, which is crucial for meeting production targets and timelines. These compressors help maintain air quality standards, reducing the risk of respiratory issues among workers exposed to mine dust. Moreover, their integration into automated systems improves process control and reliability, leading to fewer interruptions and better resource management, ultimately supporting the sustainability and economic viability of mining endeavors.