medium pressure air compressor performance evaluation in hot and humid industrial conditions

News 2025-10-24

In industrial environments characterized by high temperatures and humidity, medium pressure air compressors face unique challenges that can degrade performance. These compressors, typically operating in the 100-150 psi range, are vital for applications like pneumatic systems and material handling. Elevated heat and moisture can lead to reduced efficiency, increased energy use, and higher maintenance needs due to condensation and component wear. Evaluating their performance under such conditions is essential for ensuring reliable operation, minimizing downtime, and optimizing costs in sectors such as manufacturing and processing.

Application Scenarios

In hot and humid regions, medium pressure air compressors are commonly used in industries like food processing, where they power packaging lines that must avoid moisture-induced contamination. Similarly, in pharmaceutical manufacturing, these compressors supply clean, dry air for sensitive operations, preventing product spoilage. Tropical shipyards and automotive plants also rely on them for tasks such as sandblasting and painting, where consistent air pressure is critical despite environmental stresses. This evaluation highlights how tailored compressor selections can enhance reliability in these demanding settings.

Performance Advantages

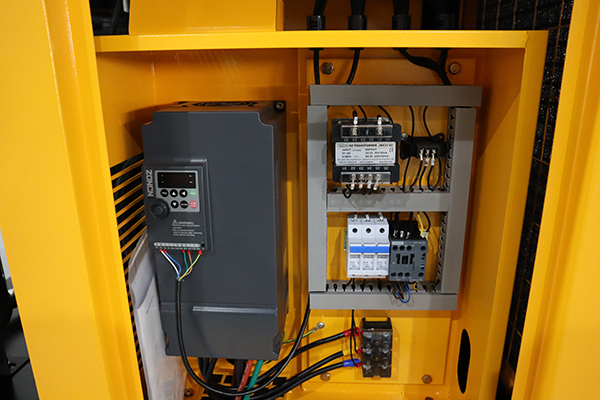

Medium pressure air compressors engineered for hot and humid conditions offer key benefits, including enhanced cooling mechanisms that maintain optimal operating temperatures and reduce thermal stress. Advanced filtration and drying systems effectively manage moisture, ensuring higher air quality and extending equipment lifespan. These features lead to improved energy efficiency, with some models achieving up to 15% better performance through variable speed drives that adjust to load demands. In evaluations, such compressors demonstrate superior durability, lowering the frequency of repairs and supporting uninterrupted industrial workflows.

Importance in Industrial Processes

The role of medium pressure air compressors in industrial processes cannot be overstated, particularly in adverse climates where they underpin critical operations. Effective performance under heat and humidity directly influences production efficiency, as any failure can cause costly delays. Moreover, reliable compressors contribute to safety by providing consistent air supply for control systems, while energy-efficient designs help meet sustainability goals by reducing emissions. Through rigorous evaluation, industries can identify upgrades that bolster resilience, ultimately driving better economic and operational outcomes in challenging environments.