medium pressure air compressor brand comparison based on durability and user feedback

News 2025-10-24

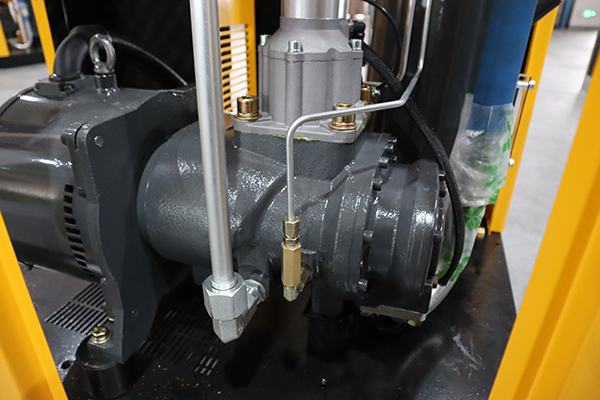

Medium pressure air compressors, operating between 20 and 100 psi, are vital in industrial settings for delivering consistent compressed air. They support applications like automotive manufacturing, where they power tools for assembly, and food processing, ensuring hygienic operations. Performance advantages include energy efficiency and reduced downtime, making them essential for maintaining productivity. This comparison focuses on durability and user feedback to evaluate how brands perform in real-world conditions, helping industries select reliable equipment for long-term use.

Ingersoll Rand Evaluation

Ingersoll Rand compressors are built with robust materials that enhance longevity in demanding environments. Users often report minimal wear after extensive use in heavy manufacturing, attributing this to features like reinforced casings and efficient cooling systems. In automotive sectors, their ability to maintain stable pressure under load improves operational efficiency, reducing errors in assembly processes. Feedback highlights strengths in ease of maintenance and parts availability, though some note higher noise levels compared to competitors.

Atlas Copco Assessment

Atlas Copco models emphasize innovative designs that boost durability, such as advanced filtration systems that protect against contaminants. In industries like packaging, users value their precise pressure control, which ensures consistent product quality and minimizes waste. Performance data shows lower energy consumption, providing cost savings in continuous operations. User reviews praise the intuitive controls and responsive service, but occasional complaints arise about initial setup complexity in larger systems.

Key Findings from Comparison

Both Ingersoll Rand and Atlas Copco excel in durability, yet they cater to different needs based on user experiences. Ingersoll Rand suits environments prioritizing brute strength and cost-effectiveness, while Atlas Copco offers superior efficiency for precision-driven tasks. Feedback indicates that durability directly impacts operational reliability, with both brands receiving high marks for reducing maintenance intervals. Industries should weigh these factors against specific application demands to optimize performance and longevity.