medium pressure air compressor for laboratory use in sample preparation and testing processes

News 2025-10-24

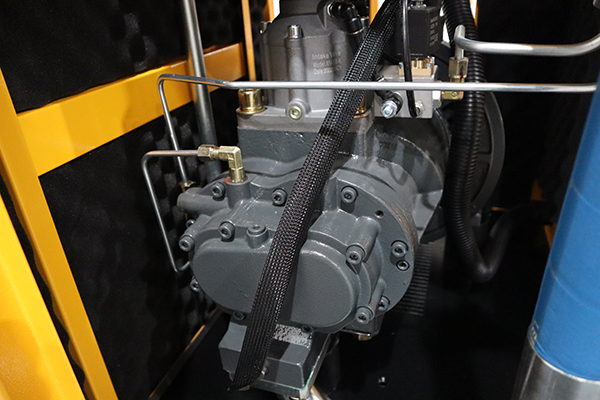

Medium pressure air compressors are essential tools in laboratories focused on sample preparation and testing. These devices deliver compressed air at pressures typically between 100 and 150 psi, supporting a variety of critical tasks. In sample preparation, they power pneumatic systems for mixing, conveying, and dispensing materials with high precision. For testing processes, they ensure reliable operation of instruments like chromatographs and spectrometers, maintaining sample integrity and reducing contamination risks. This capability enhances overall laboratory efficiency, allowing scientists to achieve accurate and reproducible results in fields such as chemistry, biology, and materials science.

Applications in Laboratory Settings

In chemical analysis, medium pressure air compressors facilitate atomization for techniques like atomic absorption spectroscopy, enabling precise sample introduction. They also drive pneumatic valves and actuators in automated systems for handling hazardous substances safely. In microbiology labs, these compressors support aeration in bioreactors or pressure-based filtration methods, crucial for culturing organisms and purifying samples. Their adaptability makes them indispensable for diverse applications, from pharmaceutical research to environmental monitoring, where consistent air supply directly impacts experimental outcomes.

Performance Advantages

One key benefit is the energy efficiency of medium pressure air compressors, which minimizes power consumption while delivering steady performance. Their compact design allows easy integration into space-constrained laboratory environments without compromising output. Oil-free models prevent lubricant contamination, ensuring that air quality meets stringent standards for sensitive analyses. Additionally, built-in filtration and drying systems reduce moisture and particulates, extending the life of connected equipment and improving the reliability of test results in repetitive use.

Importance in Industrial Processes

Beyond individual labs, medium pressure air compressors play a pivotal role in scaling up processes for industrial applications. They enable simulation of manufacturing conditions during product development, such as pressure testing components for durability. In quality control, these compressors support non-destructive testing methods that ensure compliance with industry regulations. By facilitating efficient workflows in sectors like food processing and electronics, they contribute to cost savings and innovation, underscoring their value in bridging laboratory research with large-scale production.