Industry air compressor suitable for elevator manufacturing plants

News 2025-10-27

Air compressors play a vital role in elevator manufacturing, providing the compressed air essential for various industrial processes. In elevator plants, they power pneumatic tools, control systems, and automated machinery, ensuring precision and efficiency in assembly lines. This equipment is crucial for tasks like riveting, painting, and testing, where reliable air pressure enhances productivity and safety. By delivering consistent performance, air compressors help maintain high standards in manufacturing, reducing downtime and supporting the creation of durable elevator components.

Key Application Scenarios

Elevator manufacturing involves diverse applications where air compressors excel. For instance, in welding and fastening operations, compressed air drives pneumatic hammers and drills, allowing for faster and more accurate work. In surface preparation and finishing, compressors supply air for sandblasting and painting, ensuring smooth coatings that resist corrosion. Additionally, they facilitate cleaning and drying processes, removing debris from components to meet stringent quality controls. These scenarios highlight how air compressors integrate seamlessly into elevator production, boosting operational flow and output.

Performance Advantages

Industrial air compressors offer significant benefits that make them ideal for elevator manufacturing. Their robust design ensures high pressure and flow rates, supporting heavy-duty tasks without faltering. Energy-efficient models reduce operational costs by minimizing power consumption, while advanced filtration systems deliver clean, dry air, preventing contamination in sensitive areas. Durability is another key strength, with components built to withstand harsh factory environments, leading to longer service life and lower maintenance needs. Overall, these advantages contribute to enhanced reliability and cost-effectiveness in the production process.

Common Questions

1、What types of air compressors are suitable for elevator manufacturing?

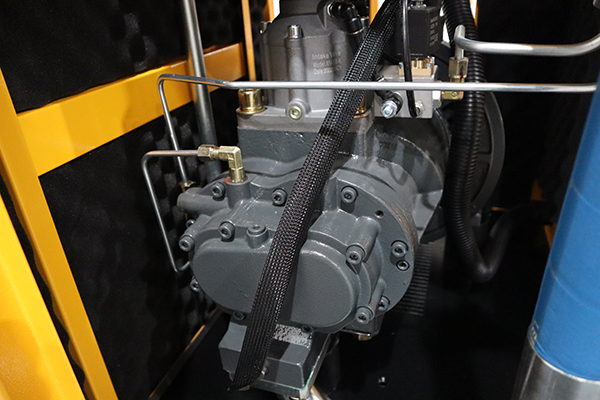

Rotary screw and reciprocating compressors are often recommended due to their reliability and ability to handle continuous operation in demanding settings.

2、How do air compressors enhance efficiency in elevator production?

They provide consistent power for automated tools, reducing manual labor and speeding up processes like assembly and testing, which improves overall productivity.

3、What maintenance practices are essential for these compressors?

Regular oil changes, filter replacements, and inspections for leaks help maintain optimal performance and extend the lifespan of the equipment.