Industry air compressor applied in automotive brake system assembly

News 2025-10-27

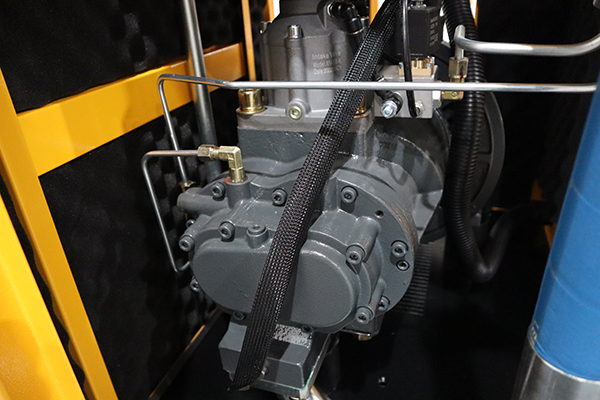

Air compressors play a crucial role in the automotive industry, particularly in the assembly of brake systems. These devices supply compressed air that powers various pneumatic tools and testing equipment, ensuring precision and reliability in manufacturing processes. In brake system assembly, air compressors are essential for tasks such as inflating tires, operating air-powered wrenches, and conducting leak tests on brake lines. This application highlights the integration of industrial technology to meet stringent safety standards, enhancing overall production quality and efficiency in automotive plants worldwide.

Application Scenarios

In automotive brake system assembly, air compressors are utilized in several key scenarios. For instance, they provide high-pressure air for hydraulic simulations that mimic real-world braking conditions, allowing engineers to test component durability and performance before installation. Additionally, compressors power automated assembly lines where pneumatic actuators assemble brake calipers and pads with high accuracy. This setup is common in large-scale manufacturing facilities, where consistent air supply minimizes errors and supports just-in-time production methods, ultimately streamlining operations and reducing costs.

Performance Advantages

The use of industrial air compressors in brake system assembly offers significant performance benefits. They deliver precise pressure control, which is vital for sensitive testing procedures that ensure brake systems meet regulatory safety requirements. Moreover, these compressors operate with high efficiency, consuming less energy while providing reliable output, which extends equipment lifespan and lowers maintenance needs. In industrial settings, this reliability translates to fewer production interruptions, enabling manufacturers to achieve higher throughput and maintain competitive edges in the fast-paced automotive market.

Frequently Asked Questions

1. What role do air compressors play in brake system testing?

They supply compressed air to simulate braking forces and detect leaks, ensuring system integrity.

2. How do air compressors enhance automotive assembly efficiency?

By powering pneumatic tools and automation, they speed up processes and reduce manual labor errors.

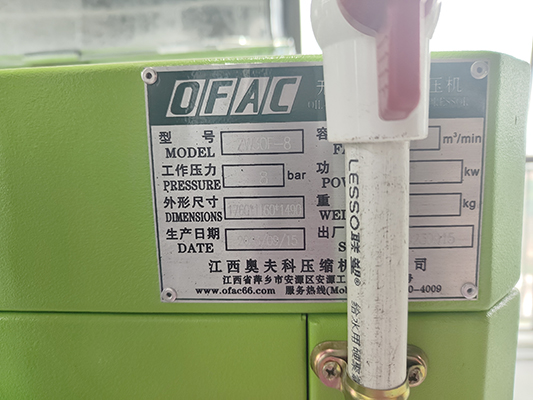

3. What features should be considered when selecting an air compressor for this application?

Focus on oil-free models to prevent contamination and compressors with variable speed drives for energy savings.