Optimized Variable Frequency Screw Air Compressors for Pneumatic System Performance

News 2025-10-31

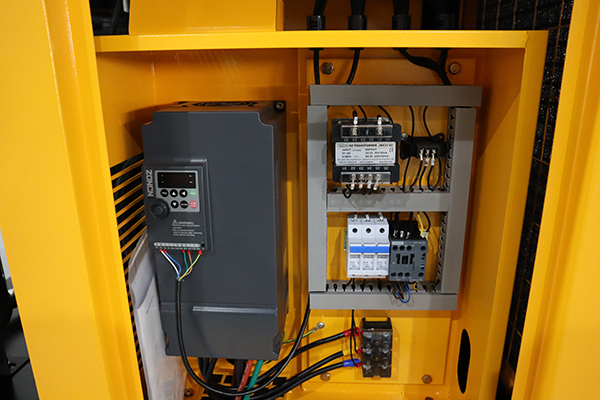

Variable frequency screw air compressors (VFSACs) are engineered to deliver superior performance in pneumatic systems by dynamically adjusting motor speed to match air demand. This optimization reduces energy waste and enhances reliability, making them vital in industries where consistent air pressure is crucial. By integrating advanced controls and efficient designs, these compressors minimize downtime and operational costs, supporting complex industrial processes that rely on precise pneumatic control for tasks like automation and material handling.

Application Scenarios

In manufacturing, optimized VFSACs power robotic arms and conveyor systems, ensuring smooth operations in high-demand environments. The automotive sector uses them for painting and assembly, where variable air flow maintains quality and reduces defects. In pharmaceuticals, these compressors provide clean, controlled air for packaging and sterilization, adhering to strict regulatory standards and improving process safety.

Performance Advantages

Optimized VFSACs offer energy savings of up to 35% through variable speed technology, which adjusts output based on real-time needs, lowering electricity bills. They also feature enhanced durability with reduced mechanical stress, extending component life and decreasing maintenance frequency. Additionally, superior pressure regulation improves system responsiveness, enabling better control in dynamic industrial settings and contributing to higher productivity and sustainability.

Frequently Asked Questions

1. What is a variable frequency screw air compressor?

A VFSAC employs inverter-driven motors to vary speed and air delivery, optimizing energy use by aligning output with demand in pneumatic systems.

2. How does it enhance pneumatic system performance?

It improves efficiency by reducing energy consumption and providing stable pressure, which minimizes wear and ensures reliable operation in varying conditions.

3. Why are they important in industrial processes?

They boost productivity by offering precise air control, cutting costs through energy savings, and supporting automation for consistent, high-quality industrial output.