Clean-output water-lubricated oil-free screw air compressor impurity-free air

News 2025-11-17

Clean-output water-lubricated oil-free screw air compressor impurity-free air solutions are reshaping how modern plants design their pneumatic systems. By replacing traditional oil-lubricated compressors, these systems deliver high-purity compressed air that helps manufacturers meet stricter safety, quality, and environmental regulations. The combination of water lubrication, oil-free screw technology, and advanced filtration minimizes contamination risks and supports stable, energy-efficient operation across demanding industrial environments.

Core Technology and Performance Features

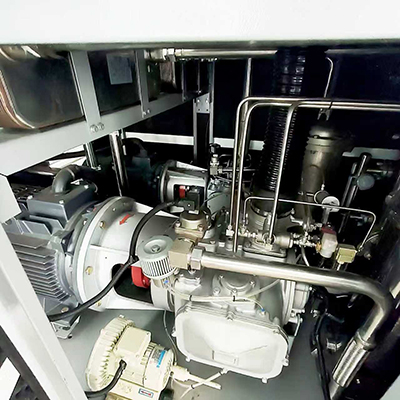

Water-lubricated oil-free screw air compressors use a carefully controlled water film to cool, seal, and lubricate the compression chamber instead of mineral or synthetic oil. This design eliminates oil carry-over and significantly reduces the concentration of solid particles in the compressed air stream. High-precision rotors, optimized inlet valves, and intelligent control systems maintain stable pressure, low discharge temperature, and reduced vibration. Inverter-driven motors further enhance part-load efficiency, lowering power consumption during fluctuating demand. The result is a compressor package that offers quiet operation, long service life, and consistent delivery of impurity-free air, suitable for critical applications.

Key Application Scenarios in Modern Industry

These compressors are widely used in industries where even trace amounts of oil or particulate contamination can damage products or compromise safety. Typical application scenarios include pharmaceutical production, where clean compressed air is needed for tablet pressing, coating, and sterile packaging; food and beverage plants, where air comes into direct or indirect contact with ingredients, bottles, or packaging films; and electronics manufacturing, where ultra-clean air protects sensitive circuits and precision assembly lines. They are also adopted in medical device production, laboratory utilities, and high-purity chemical processes, ensuring stable air quality that supports validated, repeatable, and compliant industrial operations.

Advantages for Process Stability and Sustainability

From a performance perspective, water-lubricated oil-free screw air compressors reduce the risk of product recalls, equipment fouling, and filter blockage caused by oil aerosols. The absence of lubricating oil in the compression chamber simplifies downstream filtration and reduces maintenance on dryers, filters, and pneumatic equipment. Energy efficiency is boosted by the excellent cooling capacity of water, which improves compression isothermality and reduces specific power consumption. Environmental benefits include lower carbon footprint, avoidance of oily condensate treatment, and safer working conditions. Together, these advantages make impurity-free compressed air a strategic factor in long-term production stability and sustainable plant operation.

Installation, Maintenance, and Quality Assurance

Proper system design is critical to achieve the full benefits of impurity-free air. Engineers must consider intake air quality, water treatment systems, condensate discharge, and adequate ventilation around the compressor package. Routine maintenance focuses on water quality management, filter replacement, and inspection of seals and cooling circuits, rather than oil analysis or separator changes. Many units integrate smart monitoring, allowing remote supervision of pressure, temperature, dew point, and energy performance. Documented air quality testing, aligned with ISO 8573 standards, provides objective evidence that the clean-output water-lubricated oil-free screw air compressor consistently delivers air purity suited to high-specification industrial processes.

Application Q&A

1. Where are these compressors most beneficial?

They are most beneficial in pharmaceuticals, food and beverage, electronics, and medical sectors, where impurity-free compressed air directly protects product quality and regulatory compliance.

2. How do they improve production efficiency?

By eliminating oil contamination, they reduce unplanned downtime, filter replacement frequency, and product quality issues, which helps stabilize output and lower lifecycle operating costs.

3. Do they help meet environmental regulations?

Yes, the absence of oil in the compression chamber minimizes oily condensate, reduces waste treatment requirements, and supports cleaner, more sustainable plant operation.