fixed speed screw air compressor Selection Criteria Matching Production Requirements

News 2025-12-22

Fixed speed screw air compressor Selection Criteria Matching Production Requirements

Understanding Fixed Speed Screw Compressor Basics

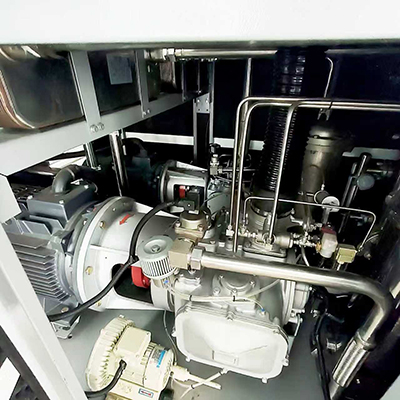

Fixed speed screw air compressors are widely used in continuous-duty industrial environments where air demand is relatively stable throughout the production cycle. Their motor runs at a constant RPM, maintaining a steady pressure band and delivering consistent airflow to downstream equipment. When selecting a fixed speed unit, engineers must evaluate not only nominal power and pressure rating, but also duty cycle, compressor type, and installation layout. Compared to small piston units, screw compressors provide smoother airflow, lower vibration, and better suitability for 24/7 operation. This makes them particularly valuable in automated manufacturing lines, process plants, and large-scale workshops where predictable air consumption is the norm.

Aligning Capacity, Pressure, and Application Scenarios

Correct sizing begins by mapping real production requirements: peak flow, base load, and allowable pressure drop across the distribution network. Industries such as metal fabrication, plastics processing, textile production, and food packaging often run stable loads that match the strengths of fixed speed screw technology. The compressor should be selected so that it operates close to its optimum load point most of the time, avoiding frequent unloaded running or excessive starts and stops. Matching rated pressure to process needs is equally critical; overspecifying pressure increases energy consumption and accelerates wear on tools and valves. A well-matched fixed speed compressor delivers consistent pressure to CNC machines, painting systems, pneumatic conveying lines, and instrumentation circuits, helping maintain product quality and process repeatability.

Performance Advantages, Efficiency, and System Integration

Although variable speed machines offer superior flexibility under fluctuating demand, fixed speed screw compressors can reach very high efficiency when the load profile is stable and properly analyzed. Key performance indicators include specific power (kW per m3/min), discharge temperature, and volumetric efficiency. Advanced screw rotor profiles, high-quality bearings, and optimized oil-injected compression stages all influence long-term performance. Integration into the plant air system is equally important: using adequately sized air receivers, low-loss dryers, and properly selected filters enhances total system efficiency. Well-designed piping, minimal pressure drops, and strategic placement of sensors and drainage points ensure that compressed air quality and pressure remain within specification across all usage points on the production floor.

Reliability, Maintenance, and Long-Term Cost Considerations

In continuous industrial processes, unplanned downtime from compressed air failure can halt entire production lines. When choosing a fixed speed screw air compressor, buyers should evaluate component quality, brand support, spare-part availability, and service network responsiveness. Lubrication quality, filtration grade, and cooling design directly affect bearing life and rotor integrity. Preventive maintenance plans, including regular oil changes, filter replacement, and leak detection, help stabilize lifecycle costs. From a total cost of ownership perspective, energy consumption remains the largest expense, so it is critical to balance initial price, efficiency rating, and expected running hours. For plants running in multiple shifts, investing in a robust, high-efficiency fixed speed unit often pays back quickly through reduced energy bills, improved process stability, and longer service intervals.

1What industries benefit most from fixed speed screw compressors?

They are ideal for manufacturing plants, metal and plastics processing, textiles, and other facilities where compressed air demand is relatively constant and production operates for long hours.

2How do I determine the correct compressor size for my production line?

Analyze average and peak air consumption of all tools and equipment, add a safety margin, consider future expansion, and then select a compressor whose optimal load range matches this stable demand.

3Why is air system design important in compressor selection?

Even a high-performance compressor will waste energy if paired with undersized piping, poor drying, or high pressure drops; proper system design preserves pressure, protects equipment, and maximizes efficiency.