Medium Pressure Water Lubricated Air Compressor

Introduction

Medium-pressure water-lubricated air compressors stand out in industrial settings by combining the advantages of water-based lubrication (oil-free, eco-friendly) with medium-pressure output (typically 1.2-4.0 MPa), addressing the demand for both clean air and higher pressure in specialized processes. This makes them a critical consideration in medium-pressure water-lubricated air compressor selection for industries where standard low-pressure models fall short, while still avoiding the oil contamination risks of traditional oil-lubricated alternatives.

In key application industries, these compressors are indispensable. The aerospace industry relies on them for aircraft component testing, such as pressurizing hydraulic systems and validating part integrity, where oil-free medium-pressure air prevents corrosion of precision parts. The automotive sector uses them in high-pressure paint spraying and tire inflation, ensuring uniform coating quality and consistent tire pressure without oil residues affecting product performance. The chemical industry also benefits, as they supply clean medium-pressure air for reactor aeration and solvent transfer, complying with strict chemical safety standards to avoid hazardous reactions with oil.

For application fields, they excel in industrial cleaning—powering high-pressure washers for heavy machinery degreasing in manufacturing plants, where water-lubricated oil-free air prevents recontamination of cleaned parts. They are also vital in marine engineering, providing medium-pressure air for ship deck equipment (like winches and cranes) and underwater tool operations, as their corrosion-resistant design adapts to harsh marine environments. Additionally, in energy storage facilities, they support compressed air energy storage (CAES) systems, leveraging medium pressure to enhance energy storage efficiency while maintaining air purity.

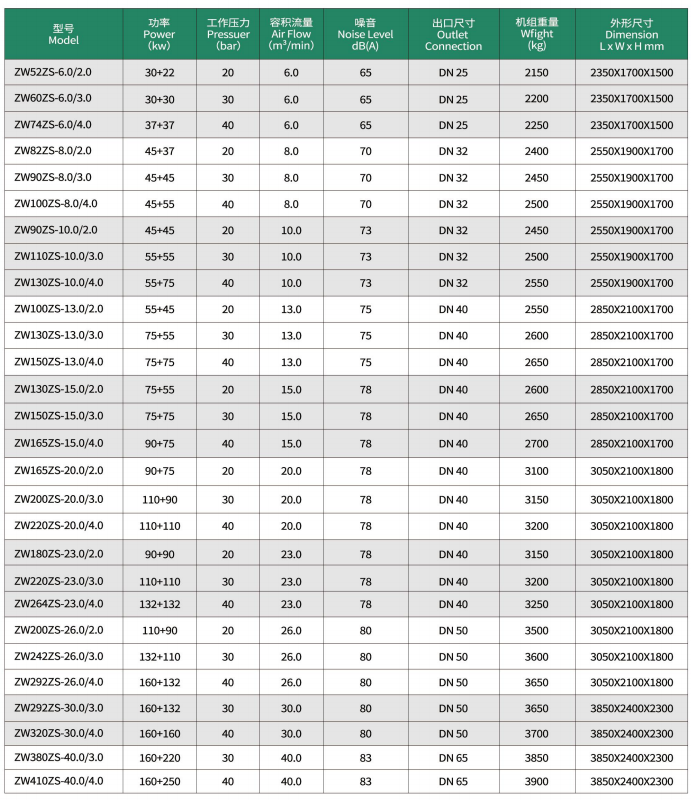

Below is a product model, specification, and parameter table to facilitate medium-pressure water-lubricated air compressor selection:

Regular medium-pressure water-lubricated air compressor maintenance is key to sustained performance: this includes monitoring water circulation systems to prevent scaling, inspecting pressure valves for leaks, and replacing wear parts (like water seals) periodically. Such upkeep not only preserves the compressor’s oil-free performance and pressure stability but also extends its lifespan, making it a cost-effective choice for industries requiring reliable medium-pressure clean air.