Normal Pressure Water Lubricated Air Compressor

Introduction

Atmospheric water-lubricated air compressors are innovative industrial equipment that use water as the lubrication medium, replacing traditional oil-based lubrication. This design not only eliminates oil contamination in compressed air but also enhances energy efficiency, making them a top choice for businesses prioritizing environmental protection and operational cost savings—key factors in atmospheric water-lubricated air compressor selection for modern industries.

In terms of application industries, these compressors excel in sectors with strict air purity requirements. The food and beverage industry relies on them for processes like ingredient mixing, packaging, and bottle blowing, as oil-free compressed air prevents product contamination and meets food safety standards. The pharmaceutical industry uses them in drug fermentation, sterile packaging, and cleanroom operations, ensuring compliance with GMP (Good Manufacturing Practice) regulations. Additionally, the electronics industry benefits from their oil-free output for semiconductor manufacturing and circuit board assembly, where even tiny oil particles can damage sensitive components.

For application fields, they are widely used in air-powered tool operations in manufacturing plants, providing consistent pressure without oil residue. They also play a crucial role in wastewater treatment facilities, powering aeration systems that support biological decomposition of pollutants. In the textile industry, they supply clean air for yarn winding and fabric finishing, maintaining the quality of delicate textiles.

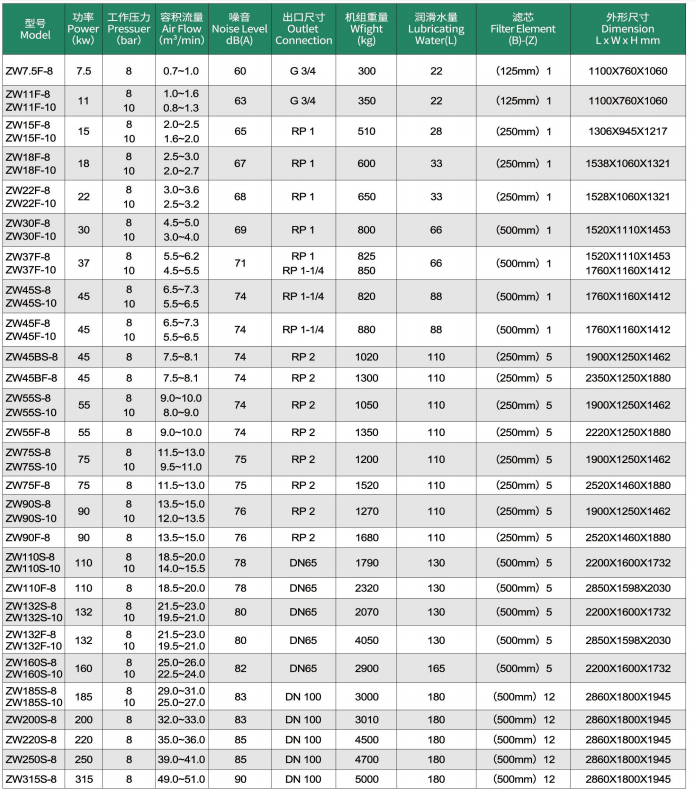

Below is a table of common product models, specifications, and parameters to support atmospheric water-lubricated air compressor selection:

To maximize performance and extend service life, regular atmospheric water-lubricated air compressor maintenance is essential—including checking water quality, cleaning filters, and inspecting seal components. This not only ensures stable operation but also maintains the compressor’s energy-saving advantages, further solidifying its value for industries seeking reliable, eco-friendly compressed air solutions.