Key Applications and Performance Benefits of Air Compressors in Modern Industries

News 2025-10-24

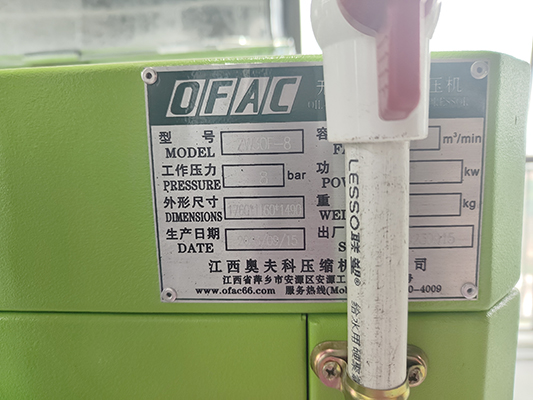

Air compressors are essential devices that convert power into potential energy stored in compressed air, serving as a cornerstone in various industrial applications. They provide a reliable source of energy for powering tools and machinery, particularly in sectors like electronics manufacturing where precision is paramount. By facilitating processes such as component assembly and testing, air compressors enhance operational efficiency and support the high standards required in modern production environments. Their ability to deliver consistent performance makes them integral to advancing industrial capabilities.

Applications in Diverse Industries

Air compressors play a vital role in electronics production, where they power pneumatic tools for tasks like soldering and component placement. In semiconductor fabrication, they enable precise wafer handling and maintain cleanroom conditions by supplying filtered air. Additionally, in automotive electronics, compressed air is crucial for testing circuits and calibrating sensors. This adaptability extends to other fields, such as medical device manufacturing, where air compressors ensure sterile environments and accurate assembly, demonstrating their broad utility in achieving high-quality outputs across multiple sectors.

Performance Advantages and Efficiency

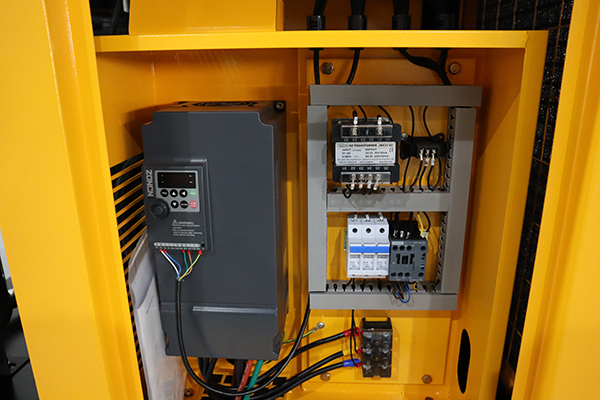

Modern air compressors offer significant benefits, including high energy efficiency that reduces operational costs through optimized power usage. They provide robust performance with durable components that withstand demanding conditions, minimizing downtime in critical applications. Features like variable speed drives allow for precise pressure control, enhancing process accuracy in electronics assembly. Furthermore, their compact designs and low noise operations contribute to safer work settings, making air compressors a smart choice for industries focused on sustainability and productivity improvements.

Frequently Asked Questions

1. What are the main types of air compressors?

Answer: The primary types include reciprocating, rotary screw, and centrifugal compressors, each designed for specific pressure and flow needs in industrial settings.

2. How do air compressors benefit electronics manufacturing?

Answer: They deliver consistent compressed air for automated tools, improving precision, reducing waste, and speeding up production cycles.

3. What key factors affect air compressor performance?

Answer: Factors such as motor efficiency, air filtration quality, and maintenance routines significantly influence reliability and longevity in various applications.