Maintenance-friendly water-lubricated oil-free screw air compressor easy upkeep

News 2025-11-17

Maintenance-friendly water-lubricated oil-free screw air compressor easy upkeep

Clean air solution for sensitive industries

Water-lubricated oil-free screw air compressors are engineered to deliver high-quality compressed air where absolute purity is critical. By using clean water as the sealing and cooling medium, they eliminate the risk of hydrocarbon contamination that can compromise food, beverage, pharmaceutical, and electronics manufacturing. This design supports strict regulatory frameworks such as GMP and HACCP, helping plants meet hygiene audits and product safety requirements. The oil-free architecture also simplifies downstream air treatment, minimizing the need for complex filtration and reducing pressure losses. For facilities operating in 24/7 production environments, this technology becomes a core element of process stability and brand protection, ensuring consistent product quality while lowering the total cost of ownership.

Performance benefits and energy efficiency

In continuous industrial service, performance and energy consumption are decisive factors. Water-lubricated oil-free screw compressors operate at lower internal temperatures, which improves volumetric efficiency and extends component life. The water seal allows tight clearances inside the compression chamber, resulting in high specific output and stable pressure delivery across varying loads. When combined with variable speed drives, these machines closely follow demand profiles, cutting energy waste during partial-load operation. Reduced mechanical friction and optimized cooling lead to lower kWh per cubic meter of air, directly supporting energy management systems and sustainability goals. Over time, energy savings and reduced maintenance interventions translate into a competitive advantage for plants in sectors such as automotive, textile, packaging, and precision engineering.

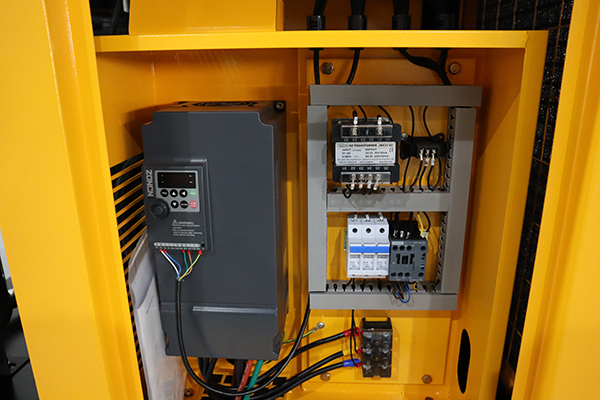

Maintenance-friendly design and easy upkeep

A key strength of this compressor type lies in its maintenance-friendly configuration. The oil-free screw element removes the need for oil sampling, oil replacement, and complex waste oil handling, significantly simplifying routine service. Transparent maintenance panels, modular component layouts, and front-access service points allow technicians to complete inspections quickly and safely. The water circuit uses corrosion-resistant materials and is usually supported by automated monitoring of temperature, flow, and water quality, reducing unplanned downtime. Intelligent controllers provide predictive alerts on filter changes, seal wear, and bearing conditions, enabling planned interventions instead of reactive repairs. This easy upkeep reduces life-cycle costs, supports higher uptime, and allows maintenance teams to focus on broader plant reliability strategies.

Key application scenarios in modern industry

These compressors play a crucial role across multiple industrial segments where clean, stable air is a process-critical utility. In food and beverage plants, they supply packaging lines, bottling systems, pneumatic conveyors, and dosing equipment without the risk of oil carryover. Pharmaceutical production relies on them for cleanroom operations, tablet pressing, coating, and sterile packaging, safeguarding both product integrity and patient safety. In electronics and semiconductor fabrication, ultra-clean compressed air helps prevent surface defects and contamination on sensitive components. Additionally, in printing, textile, and precision assembly, oil-free air protects surfaces, dyes, and adhesives from unwanted residues. Beyond product quality, the quiet and vibration-optimized design of many water-lubricated systems contributes to a safer, more ergonomic working environment.

Short questions and answers

1. Why choose a water-lubricated oil-free screw air compressor?

It delivers clean, oil-free air for sensitive processes, reduces energy consumption, and offers simplified maintenance compared to conventional oil-injected systems.

2. In which industries is this compressor most beneficial?

It is especially valuable in food and beverage, pharmaceuticals, electronics, and precision manufacturing where air purity and process stability are critical.

3. How does the design improve maintenance efficiency?

The oil-free screw element, accessible layout, automated water circuit monitoring, and smart controller diagnostics shorten service time and help prevent unplanned shutdowns.