Optimizing Industrial Efficiency with Advanced Air Compressor Technologies: A Focus on Performance and Practical Uses

News 2025-10-24

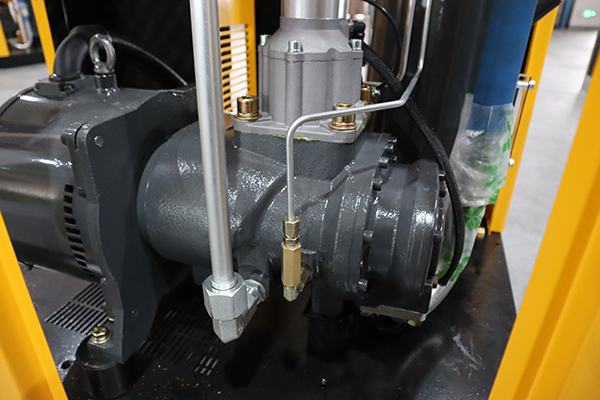

Air compressors are essential components in various industrial settings, providing the power needed for a wide range of applications. They work by converting electrical energy into kinetic energy to produce compressed air, which is used in manufacturing, construction, and automotive sectors. This technology has evolved significantly, offering improved reliability and energy efficiency that help businesses reduce operational costs and enhance productivity. Understanding the role of air compressors can lead to better integration in modern workflows, ensuring smooth and efficient operations across industries.

Applications in Various Industries

Air compressors find extensive use in multiple sectors, each leveraging their capabilities to meet specific needs. In manufacturing, they power pneumatic tools and machinery, enabling precise control and high-speed operations that boost output. The construction industry relies on them for tasks like sandblasting and painting, where portability and durability are key. Additionally, in healthcare and food processing, air compressors ensure clean, oil-free air for sensitive applications, maintaining hygiene standards and preventing contamination. This versatility makes them indispensable, adapting to diverse environments and contributing to safer, more efficient processes.

Performance and Efficiency Benefits

Modern air compressors deliver superior performance through advanced features that enhance energy savings and longevity. Variable speed drives allow for better control of air output, matching demand and reducing waste, which can lower electricity bills significantly. High-efficiency motors and improved cooling systems extend equipment life, minimizing maintenance and downtime. These attributes not only improve operational reliability but also support sustainability goals by reducing carbon footprints. Overall, the performance gains from contemporary designs provide a competitive edge, enabling industries to achieve more with less.

Frequently Asked Questions

1. What are the primary uses of air compressors?

They are mainly used to power tools, inflate tires, and operate machinery in industries like automotive and construction.

2. How do air compressors enhance energy efficiency?

By adjusting output to match demand, they reduce energy consumption and operational costs in various applications.

3. What maintenance is required for air compressors?

Regular checks of filters, oil levels, and belts are essential to ensure longevity and prevent breakdowns.