Rotary Screw Air Compressor Airflow Rate Calculations

News 2025-10-24

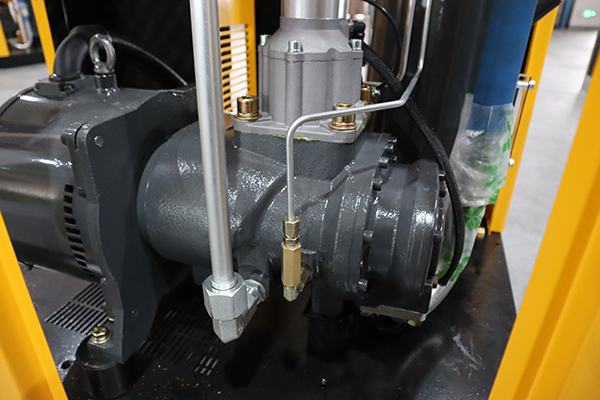

Rotary screw air compressors are integral to industrial operations, providing reliable compressed air for a wide range of applications. Accurate airflow rate calculations are essential for optimizing performance, ensuring energy efficiency, and maintaining system reliability. These calculations help determine the volume of air delivered under specific conditions, which is critical in industries like manufacturing, where consistent air supply powers tools and machinery, and in processes requiring precise control, such as pharmaceutical production. By focusing on airflow, businesses can select appropriately sized compressors, reduce operational costs, and enhance productivity in demanding environments.

Principles of Airflow Rate Calculation

The airflow rate for rotary screw compressors is calculated using key parameters such as displacement volume and rotational speed. A common approach involves the formula Q = V_d × N × η_v, where Q represents the airflow rate in cubic feet per minute (CFM), V_d is the displacement volume, N is the speed in revolutions per minute, and η_v denotes volumetric efficiency. This method accounts for real-world factors like leakage and heat, ensuring the calculation reflects actual performance under standard or site-specific conditions, such as pressure and temperature.

Factors Influencing Airflow Calculations

Several elements affect the accuracy of airflow rate determinations in rotary screw compressors. Intake temperature and pressure significantly impact air density and flow, with higher temperatures often reducing efficiency. Piping system resistance and filter conditions can cause pressure drops, altering the calculated rate. Additionally, compressor design features, like rotor profile and cooling systems, play a role in maintaining consistent airflow, making it vital to consider these variables during installation and maintenance to achieve reliable results in practical settings.

Applications and Performance Advantages

In industrial contexts, precise airflow rate calculations enable effective system integration and operation. For example, in automotive assembly lines, they ensure adequate air for robotic tools, while in food and beverage processing, they support contamination-free environments. Rotary screw compressors offer advantages such as continuous duty cycles, compact footprints, and high efficiency under varying loads, which contribute to lower energy use and extended equipment life, emphasizing their value in modern industrial workflows where dependable air supply drives success.