low pressure air compressor performance in hot and humid working environments

News 2025-10-24

In industrial settings, low pressure air compressors play a vital role in processes requiring consistent airflow, such as pneumatic tools and material handling. Hot and humid environments, common in regions like Southeast Asia or during peak summer seasons, introduce challenges that can compromise compressor efficiency and longevity. Factors like elevated temperatures and high moisture levels affect cooling mechanisms and increase the risk of corrosion, making it essential for industries to address these issues for reliable operation and cost-effective performance.

Environmental Challenges

Hot and humid conditions exacerbate wear on compressor components through thermal expansion and moisture accumulation. High temperatures can lead to increased friction and energy loss, while humidity promotes condensation that corrodes internal parts and clogs filters. This degradation not only reduces airflow capacity but also heightens the likelihood of unexpected shutdowns in critical applications, such as food processing or chemical manufacturing, where environmental control is paramount.

Performance Advantages

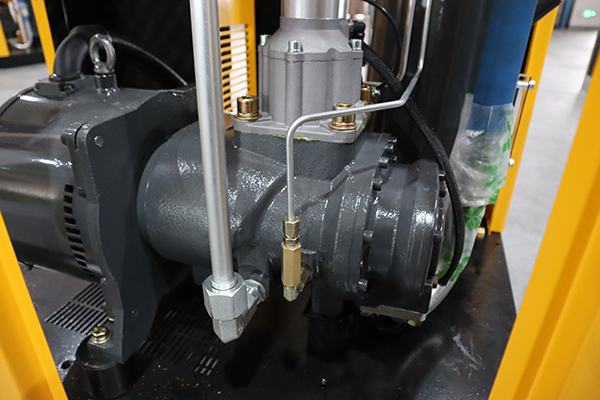

Low pressure air compressors designed for such environments feature advanced engineering, including superior cooling systems and corrosion-resistant materials, to maintain optimal performance. These enhancements ensure stable operation by minimizing heat buildup and moisture ingress, leading to lower maintenance needs and extended service life. In industrial contexts, this reliability supports continuous production, reduces energy costs, and enhances safety, making them indispensable for operations in challenging climates.

Frequently Asked Questions

1. What factors most impact compressor performance in humid settings?

Answer: Humidity causes condensation and corrosion, while heat reduces cooling efficiency, both leading to decreased reliability and higher energy use.

2. How do hot conditions affect maintenance requirements?

Answer: Elevated temperatures accelerate component wear, necessitating more frequent inspections and lubrication to prevent failures and ensure longevity.

3. Why choose low pressure compressors for these environments?

Answer: They operate with less mechanical stress and energy consumption, reducing the risk of overheating and making them ideal for sustained use in hot, humid industrial settings.