Normal Pressure Air Compressor Use in Automotive Repair Shops for Pneumatic Tool Operation

News 2025-10-24

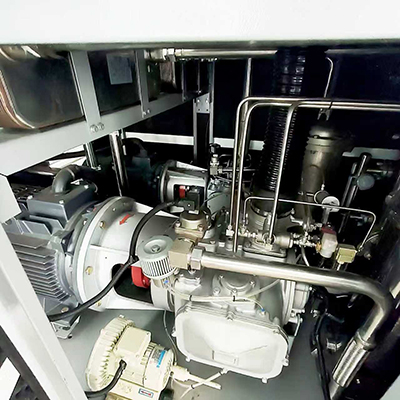

Normal pressure air compressors are essential equipment in automotive repair shops, providing the necessary power for operating pneumatic tools. These compressors generate compressed air at standard atmospheric pressures, typically ranging from 90 to 120 psi, which is ideal for tools like impact wrenches, sanders, and paint sprayers. In the fast-paced environment of auto repair, they enable efficient and precise work on vehicles, from tire changes to bodywork. By converting electrical energy into kinetic energy through compressed air, these systems offer a reliable alternative to electric tools, reducing the risk of electrical hazards and enhancing productivity in daily operations.

Application Scenarios

Normal pressure air compressors find extensive use in various automotive repair tasks. For instance, in tire services, they power impact wrenches for quick lug nut removal and inflation, ensuring accuracy and speed. In body shop applications, air compressors drive sanders and grinders for surface preparation before painting, delivering consistent performance without overheating. Additionally, in engine repair, pneumatic tools like ratchets and drills benefit from the compressor’s steady air supply, allowing mechanics to handle repetitive tasks with less fatigue. This versatility makes air compressors indispensable in both small independent shops and large dealership service centers, adapting to diverse repair needs.

Performance Advantages

One key advantage of normal pressure air compressors is their high efficiency in delivering power to pneumatic tools, often with less energy consumption compared to electric alternatives. They provide consistent torque and speed, which is critical for precision work in automotive repairs, such as tightening bolts to exact specifications. Durability is another strength; these compressors are built to withstand heavy use in harsh shop environments, with components like oil-lubricated pumps extending lifespan and reducing maintenance costs. Moreover, their ability to operate multiple tools simultaneously from a single unit boosts workflow, enabling shops to handle more vehicles efficiently and maintain competitive turnaround times.

Importance in Industrial Processes

In the broader context of industrial processes, normal pressure air compressors play a vital role in automotive repair by supporting streamlined operations and ensuring safety standards. They facilitate automated and semi-automated tasks, reducing human error in critical areas like assembly and diagnostics. By integrating with modern shop systems, such as air lines and regulators, they contribute to energy-efficient practices that lower operational costs. Ultimately, their reliability in providing clean, dry air enhances the quality of repairs, from minor fixes to complex overhauls, underscoring their significance in maintaining the efficiency and safety of the automotive industry as a whole.