Permanent Magnet Air Compressor for Optical Component Production – Dust-Free Air for Precision Manufacturing

News 2025-11-17

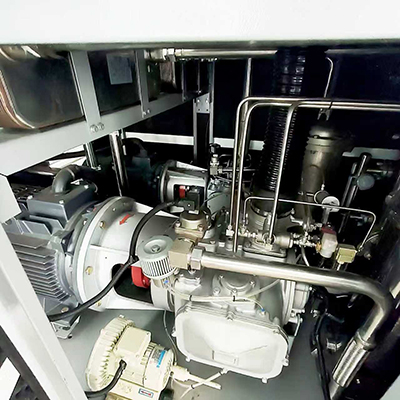

Permanent magnet air compressors are becoming a core asset in optical component manufacturing, where even microscopic contamination can compromise lens quality, coatings, and alignment accuracy. Dust-free, oil-free compressed air is required at every stage, from CNC grinding and polishing to ultra-clean coating chambers and automated inspection lines. By combining high-efficiency permanent magnet motors with advanced filtration and drying systems, these compressors provide stable, clean air that supports consistent precision and high production yields.

Clean Compressed Air for Sensitive Optical Processes

In optical workshops, compressed air is used to power actuators, purge chambers, drive polishing machines, and blow off particles from lenses, prisms, and mirrors. Any trace of oil, water, or dust carried by the air stream can scratch surfaces or interfere with thin-film coatings. A permanent magnet air compressor, paired with multi-stage filters and dryers, delivers low dew point, oil-free, dust-free air to production lines. This protects high-value components such as camera lenses, fiber-optic connectors, laser optics, and AR/VR glass, reducing scrap rates and avoiding rework.

Performance Advantages of Permanent Magnet Technology

Permanent magnet variable speed compressors operate with high energy efficiency and precise pressure control. The motor maintains high efficiency over a wide load range, cutting power consumption during partial-load operation, which is common in optical factories with fluctuating demand. Stable discharge pressure protects polishing spindles, robotic manipulators, and coating equipment from pressure drops that could disturb process parameters. Low vibration and noise support cleanroom environments and help meet strict standards for optical manufacturing facilities.

Supporting Precision, Quality, and Productivity

For optical manufacturers, compressed air quality is directly linked to product consistency and process stability. Permanent magnet compressors reduce thermal drift, improve start–stop responsiveness, and maintain continuous airflow for long coating cycles and multi-shift operation. Integrated monitoring systems can track pressure, temperature, dew point, and filter status, enabling predictive maintenance and minimizing unplanned downtime. When specified correctly, the compressor becomes a strategic component that supports higher yield, tighter tolerances, and faster delivery times.

Integration, Maintenance, and Selection Considerations

When integrating a permanent magnet air compressor into an optical plant, engineers should evaluate total air demand, cleanroom classification, acceptable dew point, and allowable oil content. Proper sizing of air receivers, pipelines, and filtration stages ensures stable distribution to lens grinding, coating, and packaging areas. Routine maintenance, including filter replacement and leak detection, preserves air purity and keeps energy costs under control. By choosing units designed for low oil carryover, efficient heat dissipation, and easy service access, optical manufacturers secure long-term performance and protect sensitive production assets.

1Why do optical plants need dust-free compressed air?

Dust-free compressed air prevents scratches, coating defects, and contamination on delicate lenses and mirrors, improving yield and maintaining high visual and dimensional quality.

2How does a permanent magnet compressor save energy?

Its variable speed permanent magnet motor adjusts output to match real air demand, reducing idle running, cutting power consumption, and lowering lifecycle operating costs.

3Can one compressor serve multiple optical production lines?

Yes, if correctly sized and supported by appropriate filtration, dryers, and piping, a single permanent magnet air compressor can serve several lines while maintaining clean, stable air supply.