medium pressure air compressor for automotive repair shops to power pneumatic tools like impact wrenches

News 2025-10-24

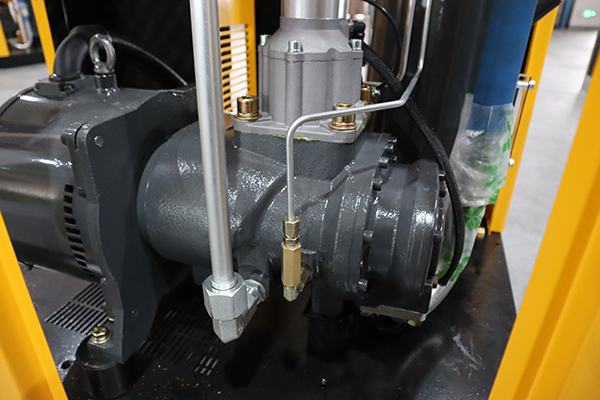

Medium pressure air compressors are vital in automotive repair shops, delivering reliable air power for tools such as impact wrenches. Operating typically between 100 and 150 psi, they provide the balanced force needed for efficient tasks like loosening bolts or inflating tires. This pressure range ensures optimal performance without excessive energy use, making them ideal for daily operations in busy environments. Their compact and durable design allows easy integration into various shop setups, enhancing overall workflow and supporting high-quality service delivery.

Applications in Automotive Repair

In automotive settings, these compressors power diverse tools that boost efficiency. Impact wrenches handle fast nut removal during tire changes, while air ratchets offer precision for engine work. Air sanders smooth body panels quickly, and drills facilitate accurate fastening, all contributing to reduced repair times. This versatility not only accelerates tasks but also minimizes physical effort, fostering safer and more productive work conditions for mechanics.

Performance Advantages

Medium pressure air compressors excel in delivering consistent air flow with minimal maintenance. They generate high torque for tools like impact wrenches, ensuring reliable operation even under heavy use. Compared to higher-pressure systems, they consume less energy and produce less noise, improving shop environments. Features such as quick pressure recovery and robust construction extend equipment life, providing cost savings and dependable performance that supports uninterrupted repair activities.

Importance in Industrial Processes

These compressors are integral to industrial efficiency in automotive maintenance, enabling seamless integration with automated systems. They ensure uniform air supply for tasks like painting and riveting, maintaining quality standards in assembly lines. By reducing downtime and enhancing precision, they play a key role in meeting production demands. Additionally, energy-efficient models align with sustainability goals, helping shops optimize resources and uphold competitive edges in the evolving automotive sector.