medium pressure air compressor use in woodworking workshops to operate sanders and nail guns

News 2025-10-24

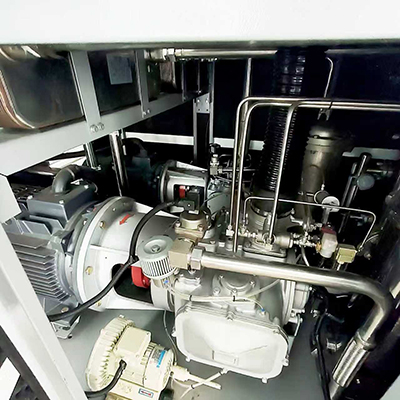

Medium pressure air compressors are essential in woodworking workshops, delivering reliable power for tools like sanders and nail guns. Operating at pressures between 100 and 150 psi, they provide a consistent air supply that enhances efficiency and precision in tasks such as surface finishing and fastening. This technology supports both small-scale crafts and industrial operations by reducing manual effort and improving output quality, making it a cornerstone for modern woodworking productivity.

Applications in Sanders and Nail Guns

In sanders, medium pressure air drives the sanding mechanism for controlled material removal, ensuring smooth finishes on various wood types. For nail guns, it supplies the force needed for quick, accurate nail driving, which speeds up assembly and minimizes errors. These applications demonstrate how medium pressure systems optimize tool performance in everyday woodworking, from detailed craftsmanship to large-scale construction.

Performance Advantages

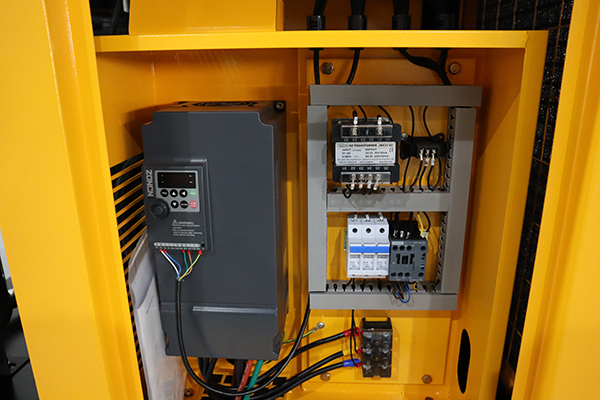

Medium pressure air compressors balance power and efficiency, consuming less energy while meeting the demands of woodworking tools. They offer fast response times and consistent air flow, which are critical for maintaining tool reliability and reducing wear. Additionally, their compact design and lower noise levels make them ideal for workshop environments, contributing to safer and more cost-effective operations over time.

Importance in Industrial Processes

In industrial woodworking, these compressors streamline processes by enabling automation and integration with other equipment, leading to higher production rates and better quality control. They help reduce human error and fatigue in repetitive tasks, while their dependability ensures minimal downtime. This reliability supports competitive manufacturing, where efficient air-powered systems are key to achieving precision and meeting market demands.