low pressure air compressor weight and size considerations for easy transportation

News 2025-10-24

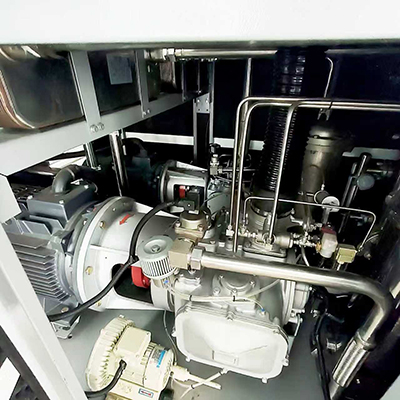

Low pressure air compressors are integral to many industrial operations, providing reliable compressed air for tools and systems in sectors like manufacturing and construction. Weight and size play pivotal roles in their transportation, as cumbersome units can lead to higher costs, safety issues, and logistical challenges. Focusing on these aspects ensures that compressors can be moved efficiently between job sites, supporting seamless workflow and adaptability. By prioritizing lightweight and compact designs, industries can enhance operational efficiency and reduce the physical demands on workers, making these compressors more practical for dynamic environments.

Design Elements Impacting Weight and Size

Several key design features influence the weight and size of low pressure air compressors. Motor type, for instance, significantly affects mass; electric motors tend to be lighter than gas-powered ones due to simpler construction. Tank capacity also contributes, with larger tanks adding weight for extended air supply but potentially unnecessary for short-term uses. Manufacturers often incorporate lightweight materials such as aluminum or advanced composites to minimize bulk without sacrificing durability. These considerations help in creating models that are easier to handle and transport, catering to applications where mobility is essential.

Advantages in Key Industrial Applications

Optimizing weight and size offers substantial benefits in various settings, improving performance and reliability. In construction, compact compressors facilitate quick relocation across sites, enabling continuous operations without delays. For automotive repair shops, reduced size allows fitting into tight spaces, enhancing workspace utilization and accessibility. In rental or event industries, lighter units simplify loading and unloading, cutting down on labor and time. These attributes not only boost efficiency but also extend equipment life by minimizing stress during movement, underscoring their importance in maintaining smooth industrial processes.

Common Questions and Answers

1. What is the average weight range for low pressure air compressors?

Typically, they weigh between 50 to 150 pounds, varying by model and features to suit different transportation needs.

2. How does compressor size affect ease of transport?

Smaller sizes enable better vehicle compatibility and manual handling, reducing the effort required for moving between locations.

3. Are there ways to reduce compressor weight without losing performance?

Yes, using high-strength materials and efficient designs can lower weight while preserving air output and reliability.