Industry air compressor suitable for paper mills powering roll adjustment mechanisms

News 2025-10-27

In the paper manufacturing industry, air compressors play a crucial role in maintaining operational efficiency and product quality. Specifically, those designed for paper mills must reliably power roll adjustment mechanisms, which ensure uniform paper thickness and minimize defects during production. These compressors deliver compressed air to pneumatic systems that control the precise movement of rolls, adapting to varying material thicknesses and speeds. By providing consistent pressure and flow, they support continuous operations in high-demand environments, reducing downtime and enhancing overall productivity. This integration is vital for meeting stringent industry standards and achieving cost-effective manufacturing processes.

Application Scenarios in Paper Mills

Air compressors are essential in several key areas of paper mill operations. For instance, in the calendering stage, they power actuators that adjust roll gaps to achieve desired paper smoothness and density. In coating applications, compressed air facilitates the precise application of substances, ensuring even coverage and reducing material waste. Additionally, these compressors support web handling systems, where accurate tension control prevents tears and inconsistencies. Their ability to operate in humid, dusty conditions makes them ideal for paper mills, where environmental factors can challenge equipment reliability, thus sustaining high-throughput production lines.

Performance Advantages

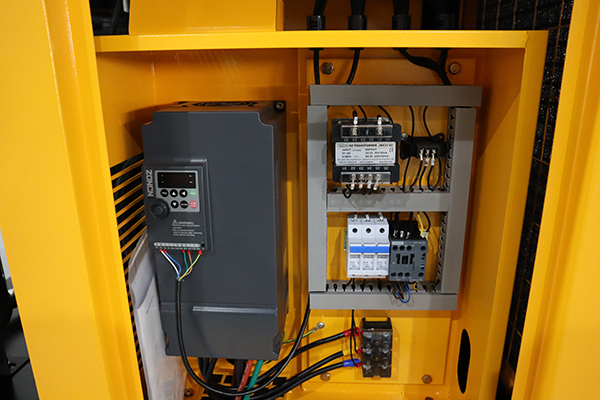

Industrial air compressors for paper mills offer superior performance through features like high-efficiency motors and advanced filtration systems, which minimize energy consumption and maintenance needs. They provide rapid response times for pressure changes, enabling quick adjustments to roll mechanisms and improving process control. Durability against corrosion and wear ensures longevity in harsh mill environments, while variable speed drives optimize air delivery, reducing operational costs. These attributes not only enhance precision in roll adjustments but also contribute to safer working conditions by automating repetitive tasks, ultimately boosting output quality and factory uptime.

Frequently Asked Questions

1. What role do air compressors play in roll adjustment?

They supply pneumatic power for accurate and swift modifications to roll positions, ensuring consistent paper quality.

2. Why are specific compressors chosen for paper mill use?

They are selected for their robustness in handling moisture and dust, along with reliable pressure output critical for industrial demands.

3. How do these compressors impact paper production efficiency?

By enabling precise adjustments, they reduce material waste and downtime, leading to higher productivity and better resource utilization.