Industry air compressor suitable for warehouse operations powering pallet wrappers

News 2025-10-27

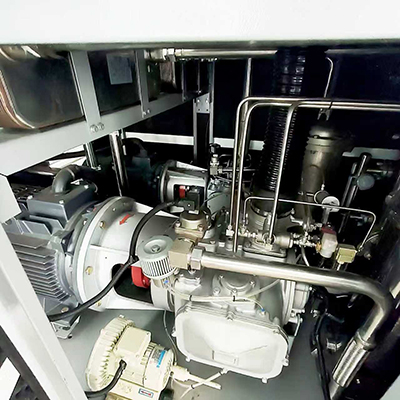

In modern warehouse environments, air compressors play a crucial role in enhancing operational efficiency. Specifically, industrial air compressors designed for powering pallet wrappers ensure that goods are securely packaged and ready for shipment. These systems provide the necessary compressed air to operate wrapping machinery, reducing manual labor and minimizing errors. By delivering consistent pressure and flow, air compressors contribute to faster turnaround times and improved safety standards in logistics and distribution centers. Their integration into warehouse workflows highlights their importance in streamlining processes and maintaining productivity.

Application Scenarios in Warehousing

Air compressors are essential in various warehouse settings, particularly for pallet wrapping tasks. In high-volume distribution centers, they power automated wrappers that encase pallets with stretch film, protecting goods during transit. This application is critical in industries like food and beverage, pharmaceuticals, and manufacturing, where product integrity must be preserved. Additionally, in cold storage facilities, compressors handle the demands of low-temperature environments, ensuring reliable performance. By adapting to different operational needs, air compressors facilitate seamless integration with conveyor systems and robotic arms, boosting overall warehouse throughput.

Performance Advantages for Industrial Use

Industrial air compressors offer significant benefits when powering pallet wrappers, including high efficiency and durability. They provide precise air delivery that optimizes wrapper speed and film tension, resulting in secure and consistent packaging. Energy-efficient models reduce operational costs by minimizing air leaks and incorporating advanced controls. Moreover, their robust construction withstands the rigors of continuous use, with features like low noise levels and easy maintenance enhancing workplace conditions. In industrial processes, these compressors ensure minimal downtime, supporting critical tasks that maintain supply chain reliability and cost-effectiveness.

Common Questions

1. What types of air compressors are best for pallet wrapping?

Rotary screw compressors are ideal due to their continuous operation and high air flow, suitable for demanding warehouse applications.

2. How do air compressors improve warehouse safety?

They enable automated wrapping, reducing manual handling risks and ensuring uniform packaging that prevents load shifts during transport.

3. What maintenance is required for these compressors?

Regular checks of filters, oil levels, and belts are necessary to ensure optimal performance and extend the lifespan of the equipment.