Industry air compressor applied in steel fabrication shops for plasma cutting tools

News 2025-10-27

Air compressors play a vital role in steel fabrication shops, particularly when powering plasma cutting tools. These machines generate high-pressure air that is essential for creating the plasma arc used to cut through thick steel plates with precision and speed. In the demanding environment of fabrication workshops, reliable air supply ensures that cutting processes run smoothly, reducing downtime and enhancing overall productivity. By delivering consistent airflow, air compressors support the intricate needs of plasma cutting, where accuracy is critical for producing components in industries like automotive, construction, and manufacturing.

Key Applications in Steel Fabrication

Steel fabrication shops rely on air compressors for various plasma cutting applications, including shaping structural beams, fabricating custom parts, and processing large metal sheets. The compressed air not only initiates the plasma arc but also helps in cooling the cutting torch and removing debris, which maintains cut quality and extends tool life. This integration allows for versatile operations, such as bevel cutting and piercing thick materials, enabling shops to handle diverse projects efficiently. In high-volume settings, air compressors facilitate automated systems, improving workflow and supporting the scalability needed for modern fabrication demands.

Performance Benefits of Air Compressors

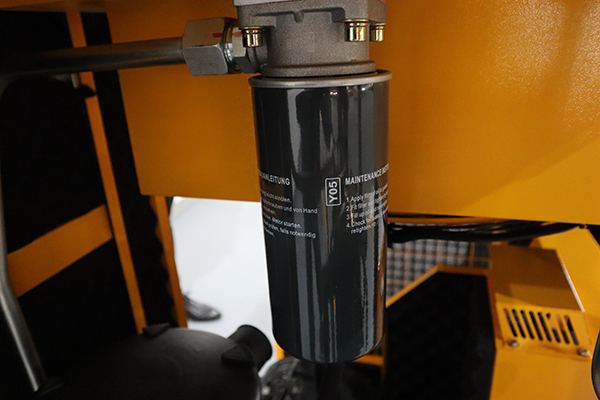

Air compressors offer significant advantages in plasma cutting by providing stable pressure and flow rates that directly impact cutting speed and edge finish. Their ability to deliver oil-free air prevents contamination, ensuring cleaner cuts and reducing the need for post-processing. Energy-efficient models help lower operational costs while maintaining high performance, making them ideal for continuous use in fabrication environments. Additionally, advanced features like variable speed drives enhance adaptability, allowing compressors to adjust to fluctuating demands without compromising reliability or safety in industrial settings.

Frequently Asked Questions

1. What is the primary function of air compressors in plasma cutting?

They supply the compressed air necessary to generate and sustain the plasma arc for effective metal cutting.

2. How do air compressors improve efficiency in steel fabrication?

By ensuring consistent air pressure, they enhance cutting precision and speed, minimizing material waste and production delays.

3. What factors should be considered when selecting an air compressor for plasma tools?

Key considerations include required pressure levels, air flow capacity, and the compressor’s durability to match the intensity of fabrication operations.