Industry air compressor applied in ceramic tile production lines

News 2025-10-27

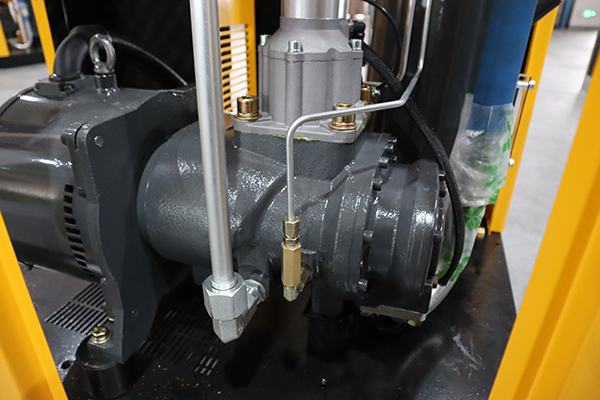

In the ceramic tile production industry, air compressors are fundamental for driving efficiency and precision across various stages. They supply compressed air to power pneumatic equipment, ensuring smooth operations from raw material processing to final product finishing. This technology supports high-volume production by maintaining consistent air pressure, which is critical for tasks like mixing, molding, and drying. As ceramic tile manufacturing evolves, the integration of reliable air compressors enhances overall productivity and product quality, making them a cornerstone of modern industrial setups.

Applications in Ceramic Tile Production

Air compressors play a vital role in specific applications within ceramic tile lines. They facilitate material conveyance by powering pneumatic systems that move powders and slurries efficiently, reducing manual handling and contamination risks. In the drying phase, compressed air aids in atomizing water-based mixtures, accelerating evaporation and ensuring uniform drying. Additionally, during tile forming and glazing, air compressors operate precision tools for accurate shaping and coating application, which directly impacts the tile’s strength and appearance. This versatility makes air compressors indispensable for maintaining workflow continuity.

Performance Advantages of Air Compressors

Industrial air compressors deliver key performance benefits that optimize ceramic tile production. Their robust design ensures high reliability, with minimal maintenance requirements to sustain long operational hours. Energy-efficient models reduce consumption by adjusting output to demand, lowering operational costs without compromising performance. Moreover, advanced filtration systems provide clean air, preventing defects caused by moisture or particles, thus upholding stringent quality standards. These attributes not only boost efficiency but also contribute to sustainable manufacturing practices in the industry.

Importance in Industrial Processes

The significance of air compressors in ceramic tile production extends to enhancing overall industrial processes. They enable precise control over production variables, such as pressure and flow rates, which are essential for achieving consistent tile dimensions and finishes. By integrating with automated systems, air compressors improve safety and reduce labor intensity, allowing for scalable operations. This reliability supports meeting market demands for high-quality tiles while minimizing waste and downtime, underscoring their critical role in competitive manufacturing environments.

Frequently Asked Questions

1. What role do air compressors play in ceramic tile production?

Answer: They provide compressed air for powering tools in material handling, drying, and finishing, ensuring efficient and precise manufacturing.

2. How do air compressors improve energy efficiency?

Answer: Through features like variable speed drives, they adjust air output to match demand, reducing energy use and operational costs.

3. What should be considered when choosing an air compressor for tile lines?

Answer: Factors include required air pressure and flow, energy efficiency ratings, durability, and compatibility with existing production systems.