Industry air compressor for aerospace component cleaning with filtered air

News 2025-10-27

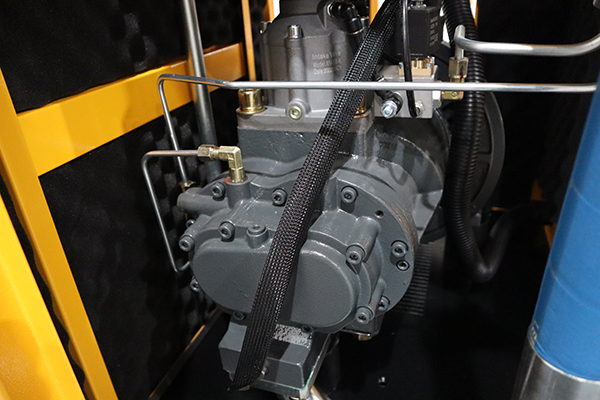

In the aerospace industry, maintaining impeccable cleanliness is vital for component reliability and safety. Industrial air compressors with filtered air systems deliver contaminant-free air, essential for removing dust, oil, and particles during cleaning. This technology supports critical processes by preventing recontamination, ensuring parts meet stringent standards like those from NASA or ISO. By integrating advanced filtration, these compressors enhance operational efficiency and longevity of aerospace components, reducing the risk of failures in high-stakes applications.

Application Scenarios in Aerospace Cleaning

Filtered air compressors are key in diverse aerospace tasks, such as blow-off cleaning for turbine blades and electronic assemblies. They excel in cleanroom settings, providing air purity that adheres to Class 100 standards, crucial for sensitive operations. In maintenance and manufacturing, these systems handle precision cleaning of structural parts and avionics, ensuring no residues affect performance. Their adaptability makes them ideal for automated lines, where consistent air quality supports high-throughput production without compromising safety.

Performance Advantages

Industrial air compressors with filtered air offer superior contaminant capture, often down to 0.01 microns, boosting cleaning effectiveness. They provide stable pressure and flow for targeted applications, minimizing damage to delicate components. Compared to alternatives, these systems are energy-efficient and require less downtime, lowering costs while upholding reliability. In aerospace contexts, their robust design ensures compliance with industry norms, delivering cleaner results that enhance component durability and system performance.

Frequently Asked Questions

1. What is the primary benefit of using filtered air in compressors?

Filtered air eliminates contaminants during cleaning, safeguarding aerospace components from potential defects and ensuring long-term reliability.

2. How do these compressors improve industrial cleaning processes?

They deliver precise, high-purity air that enhances efficiency and meets regulatory standards, reducing contamination risks in critical applications.

3. What maintenance is needed for optimal compressor performance?

Regular filter checks and replacements are essential to maintain air quality and prevent operational issues in demanding environments.