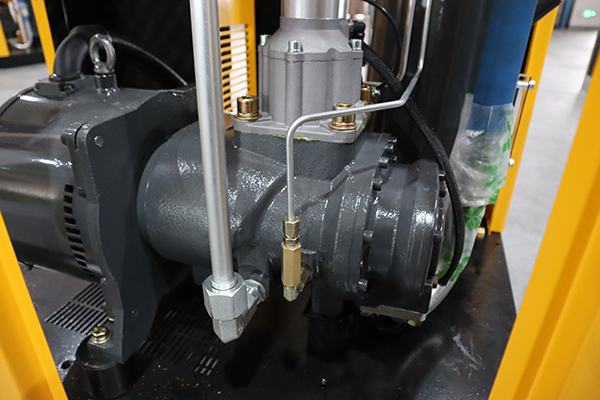

Industry air compressor for pipe manufacturing supporting extrusion processes

News 2025-10-27

In the pipe manufacturing sector, industrial air compressors are vital for extrusion processes, where they deliver compressed air to support key operations. Extrusion shapes materials like plastics into pipes by forcing them through dies, and air compressors ensure efficient cooling, material handling, and precise control of machinery. This reliability enhances production quality and speed, making air compressors essential for meeting industry demands and maintaining competitive edges in manufacturing.

Application Scenarios

Air compressors find extensive use in pipe extrusion settings. They power cooling systems that rapidly chill extruded pipes to prevent deformation, and facilitate pneumatic controls for adjusting die openings during production. In material conveyance, compressors move raw plastics or additives through pipelines, ensuring consistent flow and reducing manual handling. These applications are critical in producing various pipe types, such as those for plumbing or industrial uses, where precision and efficiency are paramount.

Performance Advantages

Industrial air compressors excel in extrusion with their robust performance features. They provide steady air pressure and flow, minimizing variations that could cause defects in pipe walls or dimensions. Energy-efficient designs reduce consumption, lowering costs, while durable components withstand harsh manufacturing environments. Additionally, integrated controls allow for real-time adjustments, optimizing output and extending equipment lifespan, thus supporting uninterrupted operations in high-demand production lines.

Frequently Asked Questions

1. What role do air compressors play in extrusion processes?

Answer: They supply compressed air for cooling extruded materials, operating controls, and handling components to ensure precise and efficient pipe formation.

2. How do air compressors enhance pipe manufacturing efficiency?

Answer: By delivering reliable air power, they speed up cooling and material movement, reducing cycle times and minimizing production waste.

3. What key factors influence the selection of an air compressor for extrusion?

Answer: Considerations include required air flow and pressure, energy efficiency ratings, and compatibility with existing extrusion systems to optimize performance.