Industry air compressor suitable for automotive battery assembly lines

News 2025-10-27

The automotive industry is rapidly evolving, with battery technology at the core of electric vehicle advancements. Industrial air compressors are vital in automotive battery assembly lines, delivering compressed air for precise operations like fastening components, applying seals, and powering robotic systems. This ensures efficient production, where consistent air supply minimizes errors and downtime. In high-stakes environments, these compressors support automated processes that handle delicate battery cells, adhering to strict quality and safety standards required in modern manufacturing.

Application Scenarios

In automotive battery assembly, air compressors enable key processes across the production line. For example, they power pneumatic tools for tightening bolts and riveting casings, ensuring secure assemblies without damaging sensitive electronics. Compressed air also drives adhesive dispensers for sealing, critical for battery longevity, and actuates robotic arms for component placement with high accuracy. Additionally, in leak testing and cleaning stages, air compressors provide controlled air flows to detect defects and remove contaminants, adapting seamlessly to the demands of automated, high-volume production.

Performance Advantages

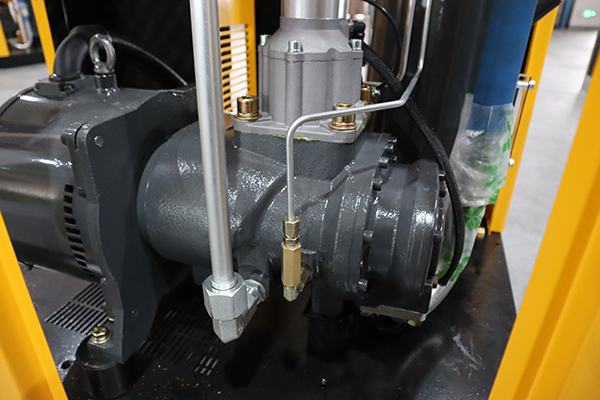

Industrial air compressors for automotive applications boast features that enhance operational effectiveness. They deliver reliable pressure and flow rates, supporting multiple tools simultaneously without fluctuations that could compromise assembly quality. Energy-efficient designs, including variable speed drives, optimize air usage and reduce costs, while durable construction handles continuous cycles in demanding settings. Integrated filtration systems ensure clean air, preventing contamination in sensitive areas, and advanced controls allow real-time adjustments, improving process reliability and extending equipment lifespan in battery manufacturing.

Frequently Asked Questions

1. What is the main function of air compressors in battery assembly?

Answer: They provide compressed air to power tools and automation for precise fastening, sealing, and handling of battery components.

2. Why choose specific air compressors for automotive use?

Answer: Models with high pressure stability and oil-free operation ensure accuracy and prevent contamination in critical assembly processes.

3. How do air compressors impact production efficiency?

Answer: By enabling faster cycle times and reducing manual interventions, they increase output and minimize errors in automotive battery lines.