Water-lubricated oil-free screw air compressor reliable industrial air supply solution

News 2025-11-17

Water-lubricated oil-free screw air compressor reliable industrial air supply solution

Clean and Stable Air for Sensitive Industries

Water-lubricated oil-free screw air compressors are engineered to deliver high-quality compressed air where strict cleanliness and process stability are mandatory. By using water instead of traditional lubricating oil in the compression chamber, these systems eliminate the risk of oil carryover into downstream equipment, pipelines, and end products. This technology is especially valued in food and beverage processing, pharmaceutical manufacturing, electronics, precision instrument production, and medical facilities, where even trace oil contamination can lead to batch rejection, product defects, or regulatory non-compliance. The oil-free design also simplifies air treatment, reducing the need for complex filtration stages while providing consistently low dew point and particle levels.

Performance Features and Energy Efficiency

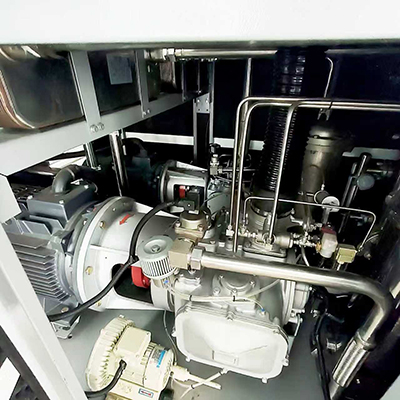

At the core of the water-lubricated screw compressor is a robust, low-wear compression element that uses water for sealing, cooling, and noise reduction. The water absorbs compression heat efficiently, allowing lower operating temperatures and improving volumetric efficiency. Many models integrate variable speed drives, optimizing motor speed according to real-time air demand and reducing energy consumption during partial load operation. Direct-drive structures minimize mechanical losses, while intelligent controllers continuously monitor pressure, temperature, and flow to maintain stable output and protect critical components. Over the service life, these features translate into lower energy bills, fewer unplanned shutdowns, and reduced maintenance costs compared with conventional oil-injected units.

Key Applications Across Industrial Processes

In food and beverage plants, oil-free, water-lubricated compressors supply clean compressed air for product conveying, bottling, packaging, and clean-in-place systems, helping producers comply with HACCP and international hygiene standards. In pharmaceutical and biotech facilities, they safeguard sterile environments, protecting mixing, fermentation, and tableting lines from contamination. Electronics manufacturers depend on oil-free air for wafer handling, SMT assembly, and precision cleaning, where microscopic residues can affect yields and device reliability. Additional applications include textile production, chemical processing, automotive painting, and high-purity laboratories, all benefiting from reduced risk of product rework, lower rejection rates, and improved overall process quality.

Importance in Reliability, Safety, and Sustainability

For continuous process industries, compressed air is often regarded as the fourth utility, alongside electricity, water, and gas. Water-lubricated oil-free screw compressors support plant reliability by offering long service intervals, simplified water management systems, and low vibration operation suitable for 24/7 duty. The absence of lubricating oil in the air end reduces the need for oil changes, condensate treatment, and hazardous waste disposal, supporting environmental compliance and sustainability targets. Lower discharge temperatures improve downstream dryer efficiency, cutting additional energy use. As manufacturers pursue ISO, GMP, and environmental certifications, deploying oil-free technology becomes a strategic choice that strengthens quality assurance, workplace safety, and corporate reputation.

Brief Q&A

1. How does a water-lubricated oil-free screw compressor reduce contamination risk?

It replaces lubricating oil in the compression chamber with water, eliminating oil carryover and greatly lowering the chance of product or pipeline contamination.

2. Where is this type of compressor most commonly used?

It is widely used in food and beverage, pharmaceutical, electronics, medical, and other industries that require clean, oil-free compressed air.

3. Does it help lower operating costs?

Yes. High efficiency, variable speed control, and reduced filtration and waste oil treatment needs work together to cut energy and maintenance expenses over the long term.