Efficient water-lubricated oil-free screw air compressor low maintenance costs

News 2025-11-17

Efficient water-lubricated oil-free screw air compressor low maintenance costs

Clean Compression for Critical Industries

Water‑lubricated oil‑free screw air compressors deliver high‑purity compressed air for sectors where contamination is unacceptable, such as food and beverage, pharmaceuticals, electronics, and precision coating. By replacing mineral oil with water inside the compression chamber, these systems eliminate the risk of oil carryover, protect downstream equipment, and support strict GMP and ISO air quality standards. The oil‑free design also minimizes environmental impact, simplifying condensate treatment and aligning plants with increasingly demanding sustainability and ESG targets.

Performance Characteristics and Energy Efficiency

This compressor technology combines stable screw rotor geometry, optimized cooling, and intelligent control logic to maintain high efficiency across varying load profiles. Water absorbs compression heat more effectively than oil, enabling near‑isothermal compression, reduced internal leakage, and lower specific power consumption. Variable speed drive options further cut energy use by matching air delivery to real‑time demand. The result is consistently high volumetric efficiency, reduced operating temperatures, quieter operation, and extended component life in continuous industrial duty.

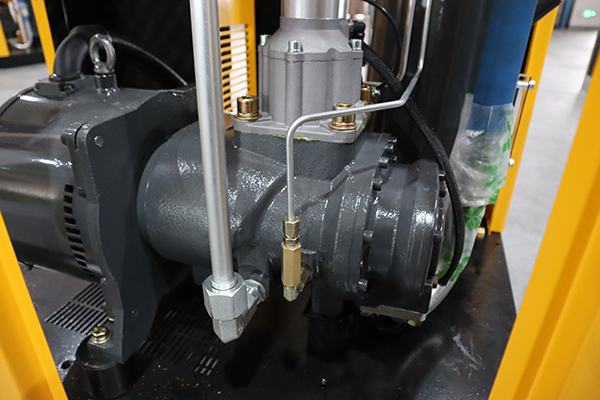

Low Maintenance Structure and Cost Benefits

The absence of lubricating oil in the compression stage eliminates frequent oil changes, oil filters, and complex separation systems, which significantly reduces scheduled service tasks and consumable costs. Simple water‑circuit management, combined with corrosion‑resistant materials, ensures long service intervals and predictable maintenance planning. Fewer wearing parts, reduced thermal stress, and integrated monitoring sensors help minimize unplanned downtime, improving overall equipment effectiveness and lowering total cost of ownership for factories running multiple shifts.

Application Scenarios in Modern Industrial Processes

These oil‑free screw air compressors are widely applied in clean packaging lines, fermentation tanks, aseptic filling, semiconductor fabrication, lab air systems, textile production, and automotive paint shops. In each scenario, stable pressure delivered by dry, clean, and oil‑free air improves process accuracy, product yield, and final surface quality. The technology also supports energy recovery solutions such as heat‑reclaim systems that preheat process water, delivering additional savings and boosting the overall efficiency of plant utilities.

FAQ on Water-Lubricated Oil-Free Screw Air Compressors

1. What industries benefit most?

They are ideal for food processing, pharma, electronics, laboratories, and any facility that requires oil‑free compressed air to protect product quality and comply with strict hygiene or cleanliness regulations.

2. How do they reduce maintenance costs?

By eliminating oil in the compression chamber, the system removes oil filter changes, separator replacement, and complex oil analysis, leaving simpler water‑system checks and longer service intervals.

3. Are they energy efficient compared to oil‑injected units?

Yes, the superior cooling capacity of water enables lower discharge temperatures, reduced leakage, and better efficiency, especially when combined with variable speed drives and optimized system design.