Long-lasting water-lubricated oil-free screw air compressor durable components

News 2025-11-17

Long-lasting water-lubricated oil-free screw air compressor durable components

Clean compression for sensitive industries

Water-lubricated oil-free screw air compressors play a critical role in sectors where air purity is directly linked to product quality and regulatory compliance. Pharmaceuticals, food and beverage processing, microelectronics, and medical facilities depend on oil-free compression to prevent contamination of products, pipelines, and precision instruments. By using water as the primary sealing and cooling medium, these compressors eliminate the risk of oil carryover and simplify downstream filtration systems. This translates into lower maintenance costs, reduced filter replacement frequency, and greater confidence in meeting strict ISO air quality standards across demanding industrial environments.

Durable components and long service life

The durability of a water-lubricated oil-free screw air compressor depends on robust core components engineered for continuous duty. High-strength stainless steel or specially coated rotors resist corrosion caused by constant contact with water, while precision-machined housings maintain tight clearances for long-term efficiency. Corrosion-resistant bearings, seals, and piping extend service intervals and protect against premature wear. Intelligent thermal management prevents overheating, safeguarding the motor and screw elements during heavy-load operation. Together, these features ensure stable performance over many years, minimizing unplanned downtime and allowing factories to maintain predictable production schedules.

Performance advantages in industrial processes

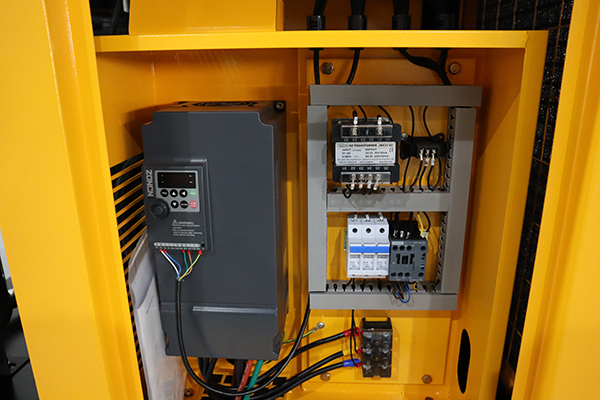

From a performance perspective, water-lubricated screw technology offers several advantages that directly impact industrial productivity. Water provides excellent heat absorption, allowing efficient cooling of the compression chamber and resulting in lower discharge temperatures. This reduces stress on downstream dryers and improves overall system efficiency. The oil-free design also minimizes pressure loss through filtration, helping maintain consistent air pressure at the point of use. Variable speed drive options further optimize energy consumption by adjusting motor speed to match fluctuating air demand. The result is stable airflow, lower kilowatt-hour usage, and a reduced carbon footprint, supporting both cost control and sustainability goals.

Application scenarios and integration flexibility

These compressors are widely deployed in clean production zones, central utility plants, and decentralized workstation supply systems. In bottling lines, packaging halls, and aseptic processing rooms, they deliver dry, clean air for actuators, valves, and pneumatic tools. In semiconductor and electronics assembly, oil-free air is critical for conveying components, controlling robotics, and purging sensitive surfaces. Many units are designed for compact installation, low vibration, and reduced noise, allowing placement close to production lines to minimize distribution losses. Integration with smart monitoring platforms enables real-time tracking of pressure, temperature, power consumption, and maintenance alerts, supporting predictive maintenance strategies in modern digital factories.

FAQ: Key points for buyers and operators

1 Main benefits of water-lubricated oil-free design

This configuration provides clean compressed air, reduced risk of product contamination, and lower filtration complexity while achieving high cooling efficiency and stable discharge temperatures.

2 Suitable industries for this compressor type

It is ideal for pharmaceuticals, food and beverage, medical gas support, electronics manufacturing, laboratories, and any process that requires high-purity compressed air.

3 How to extend compressor service life

Regularly check water quality, follow scheduled maintenance, monitor system parameters through the control panel, and use genuine spare parts to preserve efficiency and long-term durability.