Small-size water-lubricated oil-free screw air compressor compact dimensions

News 2025-11-17

Small-size water-lubricated oil-free screw air compressor compact dimensions

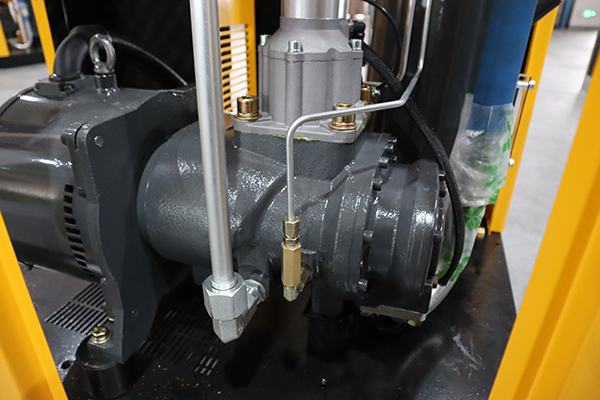

Compact architecture and core working principles

A small-size water-lubricated oil-free screw air compressor integrates a compact screw air end, high-efficiency motor, and smart controller into a minimized footprint. Instead of traditional oil injection, purified water enters the compression chamber to cool, seal, and lubricate the screw rotors, enabling oil-free compression and extremely low discharge temperatures. The reduced component count shortens the air path, improving volumetric efficiency and lowering pressure losses. This compact architecture simplifies plant layout, allowing installation in constrained technical rooms, mezzanines, or near production lines, while still meeting demanding continuous-duty industrial conditions.

Performance benefits and energy efficiency

Water lubrication delivers excellent heat dissipation and low internal leakage, resulting in higher isothermal efficiency than many oil-lubricated units of similar capacity. The compressor can achieve stable pressure, reduced specific power consumption, and faster load response. Frequency conversion control is commonly adopted to match air output to real-time demand, avoiding energy waste during partial load operation. The oil-free design eliminates pressure drops from downstream oil removal filters and minimizes pipe contamination, lowering overall system losses and maintenance costs. Together, these benefits support lower lifecycle cost and improved sustainability targets for modern factories.

Key application scenarios and process importance

Small-size water-lubricated oil-free screw air compressors are especially valued in industries where air purity and limited floor space are critical. Typical applications include food and beverage packaging, pharmaceutical manufacturing, laboratory utilities, precision electronics, medical devices, and high-quality painting or coating lines. In these scenarios, even trace oil carryover could compromise product quality, trigger recalls, or damage sensitive equipment. Oil-free, water-lubricated compression ensures clean, cool air that helps maintain process stability, protects instruments and valves, and supports compliance with strict hygiene or GMP regulations in core production areas.

Integration, maintenance, and safety considerations

The compact dimensions simplify system integration, allowing the compressor to be skid-mounted alongside dryers, filters, and air receivers to form a packaged air station. Noise-damping enclosures make it suitable for installation close to operators, reducing piping lengths and pressure drops. Maintenance mainly focuses on water quality management, regular inspection of separators, and routine checks on bearings, seals, and control valves. Because no lubricating oil enters the air stream, the risk of oil vapor emissions, flammable residues, or oil-contaminated condensate is minimized. This improves workplace safety, eases environmental management, and supports compliance with increasingly strict emission standards.

Common questions about small-size water-lubricated oil-free compressors

1. What industries benefit most?

They are ideal for food, pharmaceutical, electronics, laboratory, and medical sectors where clean, oil-free compressed air and compact installation are mandatory.

2. How does water lubrication affect maintenance?

Maintenance focuses on controlling water quality and inspecting the water circuit, while avoiding tasks related to oil changes, oil filtration, and oil disposal.

3. Can they operate continuously in harsh conditions?

Yes, when correctly sized and maintained, they support continuous-duty operation, providing stable pressure and high air quality even in demanding industrial environments.