fixed speed screw air compressor Troubleshooting Signs You Should Never Ignore

News 2025-12-22

Fixed speed screw air compressor Troubleshooting Signs You Should Never Ignore

Early warning signs in continuous-duty applications

In factories, workshops, and process plants, fixed speed screw air compressors run for long hours at a constant RPM, feeding critical equipment such as pneumatic tools, conveyors, robotics, and packaging lines. Any abnormal sign, even if production still looks normal, can signal looming downtime. Persistent pressure drops at the point of use, slow receiver recovery, and frequent pressure fluctuations are red flags that demand investigation. These symptoms often indicate air leaks, clogged filters, or internal wear in the airend. Ignoring them risks reduced output, overheating, and costly unplanned shutdowns that disrupt entire industrial processes.

Unusual noise, vibration, and temperature changes

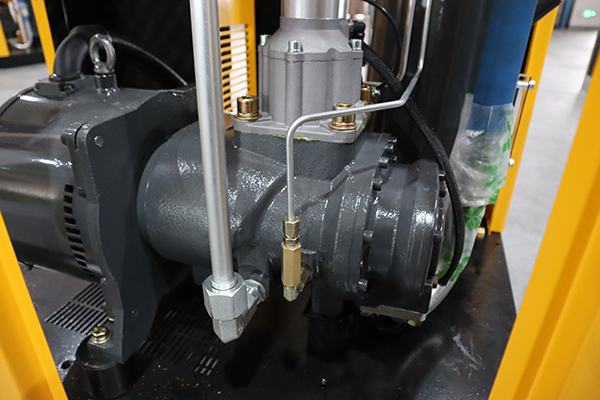

A healthy fixed speed screw compressor runs with a stable acoustic profile and predictable vibration pattern. Sudden rattling, grinding, or high-pitched whining usually points to bearing failure, misalignment, or rotor damage. Excessive vibration can propagate through the foundation, damaging piping, dryers, and downstream equipment. Equally important is temperature behaviour: rising discharge temperature, hot motor casings, or frequent high-temperature trips often signal insufficient cooling airflow, dirty coolers, or low lubricant levels. Continuous monitoring of noise, vibration, and temperature helps maintenance teams intervene early and protect both performance and service life.

Air quality issues affecting production and tools

In many industries—food and beverage, electronics, automotive, and general manufacturing—the quality of compressed air is mission-critical. Visible oil carryover, water in the lines, or recurring filter clogging are warning signs that the compressor and its treatment system are under stress. These may stem from degraded lubricant, failing separators, undersized dryers, or operation outside design conditions. Poor air quality can damage pneumatic cylinders, paint finishes, and sensitive instrumentation, increasing scrap rates and rework. Promptly addressing these symptoms preserves product quality, protects capital equipment, and maintains compliance with process standards and customer specifications.

Energy performance, controls, and maintenance indicators

Fixed speed screw air compressors are valued for stable output and robust design, but inefficiency quickly becomes expensive in energy-intensive plants. Rising power consumption at the same production load, longer unload periods, and frequent motor starts are signs of capacity mismatch, pressure band misconfiguration, or worsening leaks. Fault codes, sensor alarms, and irregular service intervals should never be dismissed or bypassed, as they often precede major failures. Using energy meters, logging pressure profiles, and following OEM maintenance schedules allows operators to detect performance drift, optimize system pressure, and minimize lifecycle cost while safeguarding reliable air supply.

Common questions about fixed speed screw air compressor troubleshooting

1, What is the most critical sign operators should monitor daily?

Abnormal pressure behaviour across the system is the most critical. Sudden drops, slow recovery, or unstable pressure often reveal underlying mechanical, control, or leakage problems affecting the entire plant.

2, How often should vibration and temperature be checked?

For continuous-duty industrial applications, vibration and temperature should be checked at least weekly on site, with continuous monitoring or logging recommended for high-value or mission-critical installations.

3, When should a plant call a professional service team?

Call professional service whenever abnormal noise, persistent alarms, or repeated trips occur, or when internal components such as bearings, airend, or motor insulation are suspected to be compromised.