fixed speed screw air compressor Component Wear Indicators To Monitor In Industrial Use

News 2025-12-22

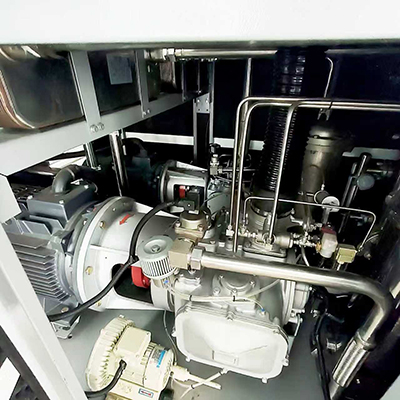

Fixed speed screw air compressor component wear indicators directly influence plant uptime, energy consumption, and product quality. In continuous-duty applications such as automotive assembly, food packaging, mining, and electronics production, unnoticed wear can cause sudden pressure loss, contamination, or catastrophic failure. Monitoring these indicators allows maintenance teams to schedule timely interventions, extend asset life, and support stable, ISO-compliant compressed air performance.

Key Wear Indicators in Air Ends and Bearings

The air end is the heart of a fixed speed screw air compressor. Rising vibration levels, unusual whining or grinding noise, and elevated discharge temperature are primary wear signals for rotors and bearings. Technicians should track bearing temperature trends, rotor axial play, and lubricant film condition. A gradual drop in delivered flow at a constant motor load often indicates internal leakage due to rotor or housing wear. In paint shops, CNC machining cells, and pharmaceutical plants, early detection of air end degradation prevents pressure instability that can compromise surface finish, machining accuracy, or product sterility.

Lubrication, Filters, and Seal Degradation

Oil-lubricated screw compressors depend on stable lubricant quality. Darkened oil, metal particles in used oil analysis, and increasing top-up frequency signal component wear. Clogged oil or air filters cause higher differential pressure, forcing the compressor to work harder, inflating specific energy consumption. Seal wear is indicated by oil carryover into the air network, visible oil mist at discharge, and oil residue in downstream dryers. In industrial painting, food-grade packaging, and electronics assembly, controlling these indicators protects product surfaces, prevents contamination, and secures long-term compliance with air purity standards.

Performance Metrics, Controls, and System-Level Symptoms

Key operational metrics such as pressure stability, duty cycle, and motor current reveal wear long before failure. A fixed speed screw unit that cycles more frequently to maintain set pressure, or shows higher amperage at the same load, may suffer from internal leakage, valve wear, or fouled coolers. Rising discharge temperature and repeated thermal trips highlight cooler fouling or fan and motor wear. In central compressor rooms supplying multi-line manufacturing, monitoring these data trends supports predictive maintenance and optimizes overall plant energy performance, aligning with ISO 50001 and corporate sustainability targets.

Monitoring Strategies and Predictive Maintenance Practices

Integrating vibration analysis, oil analysis, and continuous temperature and pressure logging enables accurate wear diagnosis. SCADA or IoT-based monitoring can trigger alerts when vibration at bearing locations exceeds threshold values or when pressure drop across filters passes manufacturer limits. Regular ultrasonic leak detection on piping and connections identifies system-side losses that mimic compressor wear. For heavy-duty users such as steel mills, glass factories, and large packaging plants, combining these techniques creates a predictive maintenance program that maximizes uptime, protects critical tooling, and minimizes unplanned shutdowns.

1、What is the most common early wear indicator?

A gradual increase in vibration and noise from the air end or bearings is often the first sign of wear in fixed speed screw air compressors.

2、How often should wear indicators be checked?

In continuous industrial operation, key indicators such as vibration, temperatures, and filter differential pressure should be reviewed at least weekly, with real-time monitoring preferred.

3、Why are component wear indicators important for energy efficiency?

Unchecked wear increases leakage, friction, and pressure drop, forcing the compressor to run longer at full load, raising specific energy consumption and operating costs.