fixed speed screw air compressor Unseen Benefits For Continuous Production

News 2025-12-22

Fixed speed screw air compressor Unseen Benefits For Continuous Production

Stable Air Supply In Demanding Industries

Fixed speed screw air compressors are widely adopted in factories that require an uninterrupted, predictable air supply. Their constant speed design delivers a continuous flow of compressed air that is ideal for assembly lines, packaging operations, and bulk material handling. In automotive welding shops, electronics plants, and food processing facilities, production cells depend on stable pressure to keep actuators, robotic arms, and pneumatic cylinders synchronized. By eliminating pressure swings, a fixed speed system minimizes product defects, reduces unplanned stops, and helps maintain consistent cycle times across multiple shifts.

Performance Advantages And Energy Management

Although they run at a constant motor speed, modern fixed speed screw air compressors are engineered for high efficiency and low specific power. Advanced rotor profiles, precise clearances, and high quality bearings reduce internal leakage and mechanical losses, translating into lower kilowatt consumption per cubic meter of air. Integrated control panels allow optimized loading and unloading, while options such as heat recovery systems capture waste heat to support space heating or preheating process water. When sized correctly to match base load demand, fixed speed units provide an excellent balance of investment cost, performance, and long-term energy savings.

Role In Continuous Production And Process Quality

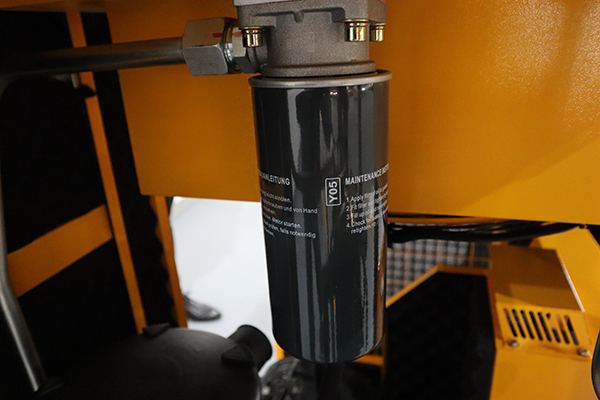

In continuous production environments, compressed air is more than a utility; it is a critical process medium. Fixed speed screw air compressors support around-the-clock operations in industries such as pharmaceuticals, textiles, glass manufacturing, and metal fabrication. Consistent pressure helps maintain coating thickness, clamping force, and cutting accuracy, directly impacting product quality and traceability. When combined with dryers, filters, and smart monitoring systems, these compressors ensure clean, dry air that protects pneumatic tools and valves from corrosion and premature wear, thereby extending maintenance intervals and reducing lifecycle costs.

Application Scenarios And System Integration

These compressors are commonly installed as the backbone of central compressor rooms, forming the base load of a plant’s air system. Typical applications include powering conveying systems in cement plants, blow molding in plastics production, and instrument air in chemical processing. Integration with air receivers, distribution piping, and pressure control valves ensures the system can meet peak demand without compromising stability. Many facilities pair a fixed speed unit for base load with a variable speed machine to handle load fluctuations, creating an energy efficient hybrid solution that supports expansion and future automation projects.

Key Questions About Fixed Speed Screw Air Compressors

1、Where are fixed speed screw air compressors most suitable?

They are best for applications with steady, predictable air demand, such as continuous production lines, central compressor stations, and processes that run at a constant load over long periods.

2、How do they support product quality in industrial processes?

By maintaining stable pressure and air volume, they keep pneumatic equipment operating within design parameters, which reduces variations in torque, clamping, spraying, and cutting performance.

3、What factors matter when selecting a fixed speed screw air compressor?

Key factors include base load airflow, required pressure, duty cycle, air quality needs, energy efficiency, available space, and the ability to integrate with dryers, filters, and monitoring systems.