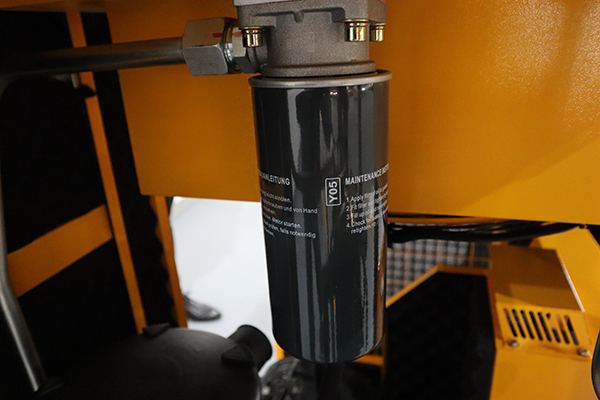

Industry air compressor used in boiler maintenance for tube cleaning equipment

News 2025-10-27

In industrial settings, boilers are critical for processes like steam generation in power plants and manufacturing facilities. Over time, tube deposits such as scale and soot can accumulate, reducing efficiency and risking equipment failure. Air compressors are essential in tube cleaning systems, providing high-pressure air to power tools that remove these build-ups. This ensures optimal boiler performance, enhances safety, and minimizes downtime, making air compressors a key component in maintaining industrial operations.

Applications in Tube Cleaning

Air compressors are widely utilized in various tube cleaning methods for boilers. In soot blowing systems, they deliver compressed air to clear ash and residues from heat exchange surfaces, improving combustion efficiency. They also support dry air blasting techniques, where high-velocity air streams dislodge stubborn deposits without water, ideal for environments where moisture could cause corrosion. Additionally, in automated cleaning setups, air compressors provide consistent pressure for precise and thorough maintenance, crucial in sectors like chemical processing and energy production to sustain productivity.

Performance Advantages

Air compressors excel in boiler tube cleaning due to their robust performance features. They generate high-pressure air that effectively eliminates deposits, boosting heat transfer rates and reducing energy consumption. With designs focused on durability and efficiency, these compressors handle continuous operation in harsh conditions, lowering maintenance needs and costs. Their ability to integrate with advanced control systems ensures precise cleaning, enhancing boiler longevity and reliability, which is vital for uninterrupted industrial processes and compliance with safety standards.

Frequently Asked Questions

1. What role do air compressors play in tube cleaning?

They supply high-pressure air to remove deposits from boiler tubes, improving efficiency and preventing failures.

2. Why are air compressors preferred for boiler maintenance?

Their high pressure and reliability make them effective for thorough cleaning while minimizing equipment damage and downtime.

3. How do they contribute to industrial efficiency?

By ensuring clean tubes, they enhance heat transfer, reduce fuel use, and extend boiler life, supporting cost-effective operations.