Low Pressure Water Lubricated Air Compressor

Introduction

Low-pressure water-lubricated air compressors are widely recognized in industrial and commercial settings for their combination of water-based lubrication (ensuring oil-free air) and low-pressure output (typically 0.4-1.0 MPa). This design meets the demand for clean, stable compressed air in scenarios where high pressure is unnecessary, making low-pressure water-lubricated air compressor selection a priority for businesses seeking cost-effective, eco-friendly solutions—while avoiding the oil contamination risks of traditional oil-lubricated compressors.

In key application industries, these compressors play a vital role. The food processing industry relies on them for tasks like dough mixing, food packaging, and beverage bottling, as oil-free low-pressure air prevents product contamination and complies with food safety regulations (such as FDA standards). The healthcare sector uses them in dental clinics (for air-driven tools like drills) and hospital cleanrooms (for air circulation systems), where clean air is critical to avoid cross-contamination. The textile industry also benefits, utilizing low-pressure air for yarn tensioning and fabric drying, as oil-free air preserves the softness and quality of textiles.

For application fields, they excel in small-scale manufacturing—powering pneumatic tools (like nail guns and spray guns) in furniture production, where low pressure ensures safe, precise operation without damaging materials. They are also essential in wastewater treatment plants, supplying low-pressure air for aeration tanks to support aerobic bacteria that break down organic pollutants, with water-lubricated design reducing maintenance costs. Additionally, in commercial settings like car washes, they power low-pressure air dryers for vehicles, delivering gentle airflow that avoids scratching paint while maintaining oil-free performance.

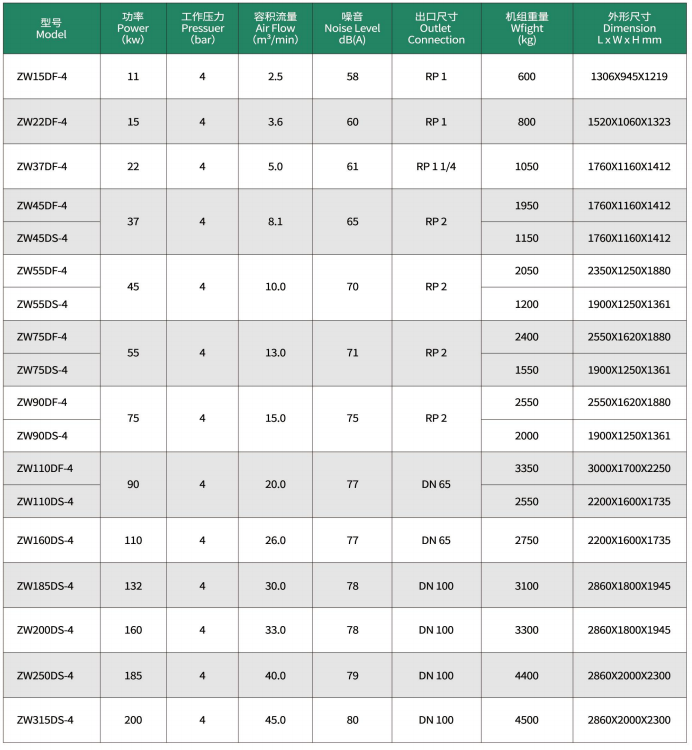

Below is a product model, specification, and parameter table to simplify low-pressure water-lubricated air compressor selection:

Regular low-pressure water-lubricated air compressor maintenance is essential for long-term reliability: this includes checking water levels to ensure proper lubrication, cleaning air filters to maintain airflow, and inspecting water seals for leaks. Such upkeep preserves the compressor’s oil-free operation, reduces energy consumption, and extends its lifespan—reinforcing its value as a dependable solution for industries and fields needing low-pressure clean air.