Micro-Oil Permanent Magnet Variable Frequency Screw Air Compressor

Introduction

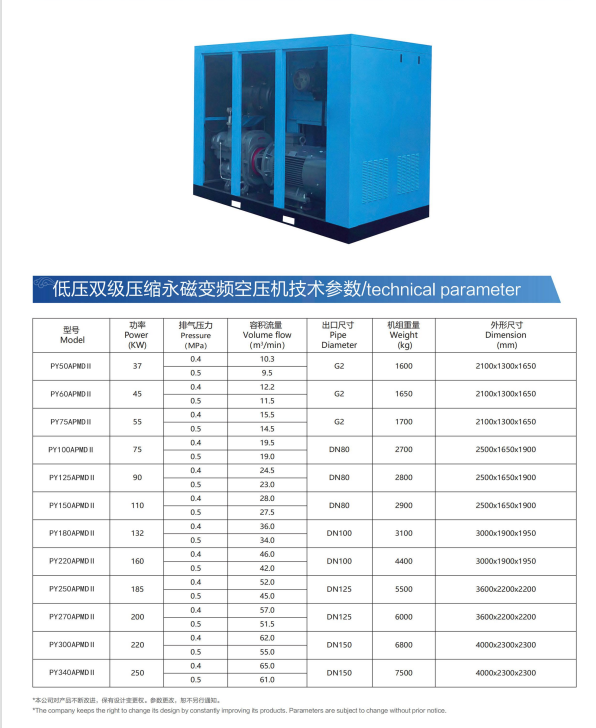

Micro-oil permanent magnet variable frequency (PMVF) screw air compressors integrate advanced PM motor technology, variable frequency control, and micro-oil lubrication, delivering efficient, stable compressed air while balancing energy savings and air quality. This makes them a top choice in micro-oil permanent magnet variable frequency screw air compressor selection for industries needing both reliable performance and reduced operational costs—addressing key search needs like energy efficiency and long-term usability.

In core application industries, these compressors excel. The manufacturing sector relies on them for assembly line pneumatic tools (e.g., riveters, grinders) and automated equipment power, as variable frequency control adjusts output to match real-time demand, cutting energy waste by 20%-30% compared to fixed-speed models. The automotive industry uses them in parts cleaning, painting prep, and engine testing, where micro-oil lubrication ensures air purity (oil content ≤3ppm) to avoid defects in vehicle components. The electronics industry also benefits, supplying compressed air for circuit board soldering and component assembly, with stable pressure preventing damage to sensitive microchips.

For application fields, they are ideal for medium-sized factories requiring continuous air supply, such as machinery processing plants, where their compact design saves floor space while maintaining high displacement. They also perform well in logistics and warehousing, powering pneumatic conveyors for goods transport and automated sorting systems, with low noise (≤75dB(A)) suitable for indoor operations. Additionally, in plastic and rubber manufacturing, they support injection molding machines by providing consistent pressure for material extrusion, ensuring product uniformity.

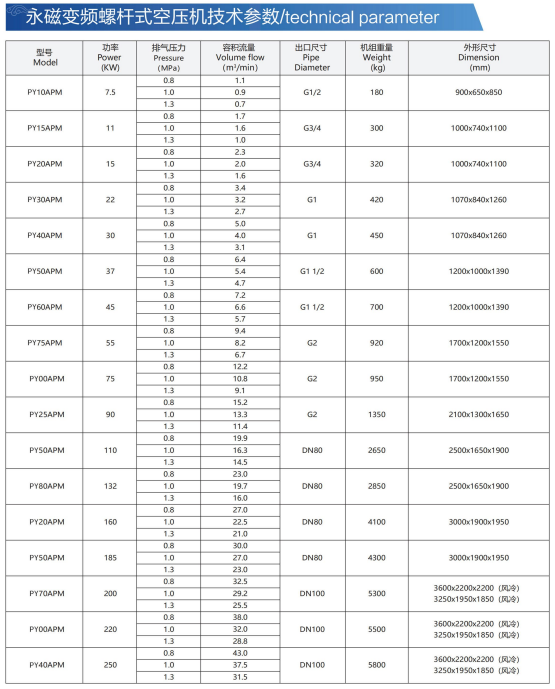

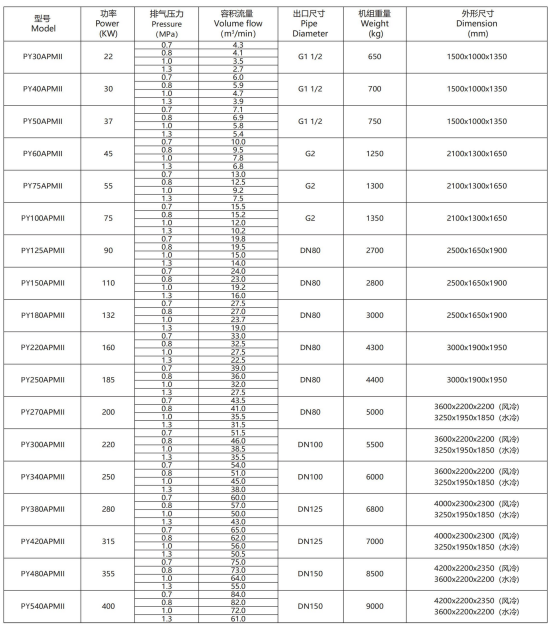

Below is a product model, specification, and parameter table to simplify micro-oil permanent magnet variable frequency screw air compressor selection:

Regular micro-oil permanent magnet variable frequency screw air compressor maintenance is crucial for sustained performance: this includes checking oil levels and quality, cleaning or replacing air filters, and inspecting PM motor windings for overheating. Proper upkeep not only preserves energy efficiency and air purity but also extends the compressor’s lifespan to 8-10 years, making it a cost-effective investment for businesses prioritizing productivity and sustainability.