Rotary Screw Air Compressor Startup Procedure Steps

News 2025-10-24

Rotary screw air compressors are essential in various industrial applications, including manufacturing, automotive assembly, and construction sites, where they provide a reliable source of compressed air for powering tools and machinery. These compressors offer significant performance advantages, such as high efficiency, continuous operation, and reduced energy consumption compared to other types. Proper startup procedures are critical to ensure safe operation, prevent equipment damage, and maintain optimal performance in demanding industrial environments. By following a structured approach, operators can extend the lifespan of the compressor and minimize downtime, which is vital for productivity in sectors relying on consistent air supply.

Pre-Startup Checks

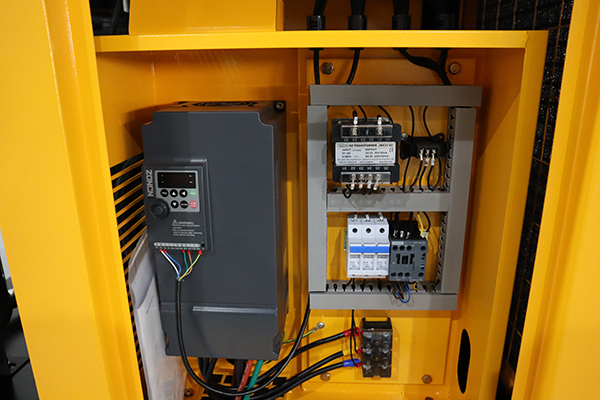

Ensuring all components are in good condition before starting a rotary screw air compressor involves several key inspections. First, verify oil levels and quality to avoid lubrication failures that could lead to overheating or wear. Check air filters for clogs and replace them if necessary to maintain airflow efficiency. Inspect electrical connections and safety devices, such as pressure relief valves and emergency stops, to confirm they function correctly. Additionally, examine belts, couplings, and hoses for signs of damage or wear. These steps help identify potential issues early, reducing the risk of breakdowns during operation and supporting the compressor’s reliability in high-stakes industrial settings.

Initiating the Startup

The startup process begins with powering on the control system and allowing the compressor to initialize. Open inlet valves gradually to prevent sudden pressure surges that might strain the system. Activate the motor and monitor the compressor’s ramp-up phase, ensuring it reaches operating speed smoothly. During this stage, listen for unusual noises and check for vibrations, which could indicate misalignment or other problems. Proper sequencing is crucial for achieving efficient performance, as it allows the compressor to build pressure steadily while protecting internal components from stress. This methodical approach enhances the unit’s durability and supports its role in continuous industrial processes.

Post-Startup Monitoring

After startup, continuous monitoring is essential to maintain optimal performance and safety. Track key parameters like discharge pressure, temperature, and flow rates using built-in gauges or digital interfaces. Make adjustments to settings, such as load/unload controls, based on real-time demands to optimize energy use and prevent overloads. Regularly inspect for leaks and ensure cooling systems are effective to avoid overheating. This ongoing vigilance helps sustain the compressor’s efficiency and longevity, making it a dependable asset in industrial operations where air quality and reliability directly impact production outcomes.