normal pressure air compressor performance evaluation in hot and humid working environments

News 2025-10-24

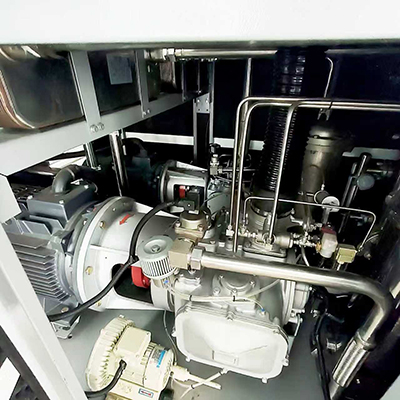

Normal pressure air compressors are essential components in a wide array of industrial sectors, including manufacturing, mining, and automotive assembly, where they provide the necessary compressed air for powering tools and automating processes. The performance evaluation in hot and humid working environments is particularly important because these conditions can exacerbate issues like thermal expansion, moisture ingress, and reduced air density, all of which degrade compressor efficiency and reliability. By conducting thorough evaluations, industries can select or design compressors that mitigate these effects, ensuring consistent performance. Common application scenarios encompass operations in Southeast Asian factories, Gulf region oil refineries, and Brazilian agricultural facilities, where high heat and humidity are normative.

Challenges in Hot and Humid Environments

Hot and humid environments present several key challenges that can impair the functionality of normal pressure air compressors. Increased ambient temperatures elevate the risk of overheating, which can damage internal components such as valves and pistons, leading to frequent breakdowns and higher maintenance costs. High humidity levels introduce moisture into the air supply, potentially causing rust in metal parts and fostering bacterial growth in air lines, which compromises the quality of compressed air and poses health risks in sensitive applications like pharmaceuticals or food production. The decreased air density in humid conditions reduces the mass flow rate, forcing the compressor to consume more energy to deliver the same volume of air, thus increasing operational expenses and environmental impact.

Performance Evaluation Techniques

To accurately evaluate the performance of air compressors in hot and humid conditions, engineers employ a variety of standardized tests and metrics. This includes assessing parameters such as volumetric efficiency, power consumption, and discharge temperature using specialized equipment like psychrometers and flow meters within controlled environmental chambers. Compressors that incorporate innovative features, such as variable speed drives and integrated drying systems, exhibit superior performance by maintaining optimal operating temperatures and minimizing moisture content. These evaluations not only highlight the advantages in energy savings and extended service life but also guide the selection of models best suited for specific industrial needs, enhancing overall system reliability.

Role in Industrial Processes

The significance of evaluating air compressor performance in hot and humid environments extends to the core of industrial processes, where downtime can result in substantial financial losses and safety hazards. In sectors like textile manufacturing or paper production, where consistent air pressure is critical, reliable compressor operation ensures smooth workflow and product quality. By prioritizing performance evaluations, companies can implement preventive measures, such as regular maintenance schedules and the use of high-efficiency filters, to counteract environmental challenges. This proactive approach contributes to sustainable industrial practices, reducing energy consumption and emissions while fostering a safer working environment.