normal pressure air compressor filter replacement schedule to maintain air quality

News 2025-10-24

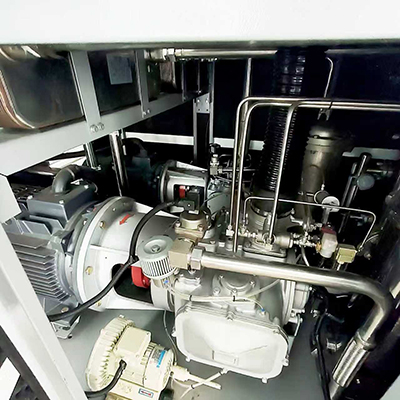

Maintaining high air quality in industrial applications relies heavily on the proper maintenance of normal pressure air compressors, particularly through regular filter replacements. Air filters play a critical role in removing contaminants such as dust, oil, and moisture, which can degrade compressor performance and affect end-product quality. This article provides a detailed schedule for filter replacement to ensure consistent air purity and operational efficiency, helping businesses avoid costly downtimes and maintain reliable systems.

Application Scenarios

Normal pressure air compressors are essential in diverse industries where clean air is vital. In automotive manufacturing, they provide contaminant-free air for painting and assembly to ensure flawless finishes. The food and beverage industry depends on filtered air to uphold hygiene standards and prevent bacterial contamination during processing. In electronics production, pure air protects delicate components from particulates that could lead to defects or failures. Pharmaceutical operations require high-purity air to comply with strict regulations, making filter maintenance indispensable for product safety and efficacy.

Performance Advantages

Regular filter replacement significantly boosts compressor performance by reducing energy consumption and minimizing strain on mechanical parts. Cleaner air enhances the efficiency of the entire system, leading to lower operational costs and extended equipment lifespan. It also improves the quality of compressed air used in precision applications, reducing the risk of contamination-related issues and ensuring consistent output. By preventing blockages and pressure drops, timely changes support smoother operations and contribute to overall system reliability in demanding environments.

Importance in Industrial Processes

Air filters are crucial for safeguarding industrial processes against the risks posed by poor air quality. Contaminants can cause machinery failures, compromise product integrity, and create health hazards for workers, potentially resulting in regulatory fines or production halts. Adhering to a replacement schedule helps maintain optimal air standards, fostering a safer workplace and supporting efficient workflows. This practice not only protects investments in equipment but also promotes sustainability by reducing waste and energy use associated with inefficiencies.

Recommended Replacement Schedule

Determining the right filter replacement interval involves assessing factors like operational hours, environmental conditions, and compressor usage. Typically, filters in normal pressure systems should be changed every 500 to 1000 hours or every three to six months, based on regular inspections. In high-dust or humid settings, more frequent replacements may be needed to sustain air quality. Conducting routine checks for pressure differentials and following manufacturer recommendations ensures that filters are replaced proactively, maintaining peak performance and air purity.