low pressure air compressor for printing small shops to power inkjet tools

News 2025-10-24

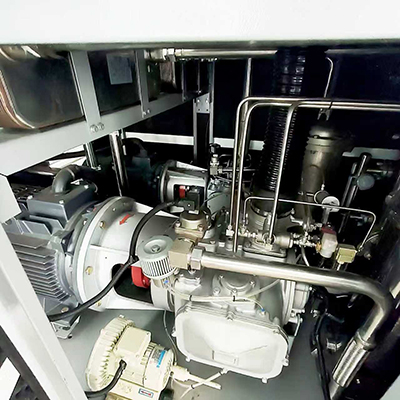

In the printing industry, low pressure air compressors are essential for small shops that rely on inkjet technology. These devices provide a controlled air supply to power inkjet tools, ensuring precise ink delivery and high-quality prints. Unlike high-pressure systems, low pressure compressors operate efficiently at reduced energy levels, making them cost-effective for businesses with limited budgets. They support various printing tasks by maintaining consistent air flow, which is critical for avoiding issues like ink splatter or uneven application, ultimately enhancing productivity in compact settings.

Applications in Small Printing Shops

Low pressure air compressors find extensive use in small printing environments for tasks such as driving inkjet nozzles and supporting automated maintenance routines. For example, they deliver air to atomize ink particles, enabling sharp, detailed outputs on materials like paper and fabrics. In shops handling custom orders or short-run prints, these compressors facilitate quick setup and operation of pneumatic tools, including cleaning systems that prevent nozzle blockages. This versatility makes them indispensable for space-constrained operations where reliability and ease of use are paramount.

Performance Advantages

These compressors excel in energy efficiency, consuming less power due to their lower operating pressures, which translates to reduced utility costs for small businesses. They also generate minimal noise and heat, creating a more comfortable workspace without compromising performance. With fewer moving parts, maintenance is straightforward, extending equipment longevity and minimizing downtime. In inkjet applications, the steady air output ensures uniform ink dispersion, reducing defects and supporting higher print speeds, which is vital for meeting tight deadlines in competitive printing markets.

Frequently Asked Questions

1. What pressure range is suitable for inkjet tools?

Answer: Inkjet tools typically require 20 to 50 psi, where low pressure compressors provide optimal efficiency and reliability.

2. Why choose a low pressure compressor for small shops?

Answer: It offers cost savings through lower energy use and simple maintenance, while delivering consistent performance essential for daily printing operations.

3. How to maintain a low pressure air compressor?

Answer: Regular checks of filters and oil levels, along with periodic inspections, help ensure longevity and prevent operational issues in printing applications.