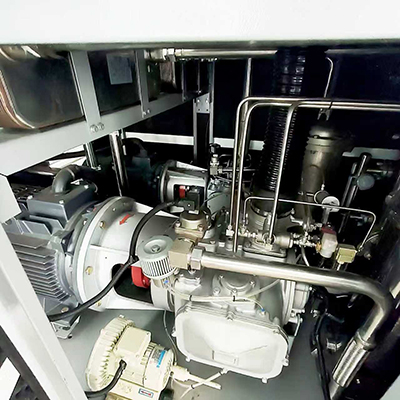

Industry air compressor suitable for aluminum extrusion plants

News 2025-10-27

In the aluminum extrusion industry, air compressors are essential for powering pneumatic systems that drive machinery and control processes. They provide compressed air for tasks like operating extrusion presses, cooling profiles, and handling materials, ensuring efficient and reliable production in demanding environments. Selecting a compressor optimized for this sector enhances operational performance and longevity.

Application Scenarios in Aluminum Extrusion

Air compressors play a key role in various applications within aluminum extrusion plants. They power actuators for precise die movement and press operations, support air conveyance systems for material transport, and enable rapid cooling of extruded shapes to maintain structural integrity. This adaptability boosts automation, reduces cycle times, and improves overall plant efficiency by integrating seamlessly with existing equipment.

Performance Advantages of Industrial Air Compressors

These compressors offer superior performance with features like high-efficiency drives that minimize energy use and advanced filtration to deliver clean air, protecting sensitive components. Their durable construction handles high temperatures and contaminants, while variable speed controls ensure optimal pressure and flow. This results in lower maintenance costs, reduced downtime, and enhanced reliability, making them ideal for continuous industrial operations.

Importance in Industrial Processes

Air compressors are critical for maintaining process stability in aluminum extrusion, where consistent air supply prevents defects and ensures product quality. They facilitate automation in handling and cooling, reducing human error and safety risks. By optimizing energy consumption and supporting high-throughput production, they contribute to cost savings and competitiveness, underscoring their value in modern manufacturing workflows.

Frequently Asked Questions

1. What is the primary role of an air compressor in aluminum extrusion?

Answer: It supplies compressed air for driving machinery, controlling processes, and cooling operations to ensure efficient and precise extrusion.

2. Why is durability important for air compressors in this industry?

Answer: Durability allows compressors to withstand harsh conditions like high heat and contaminants, reducing failures and maintenance needs.

3. How do air compressors impact energy costs in extrusion plants?

Answer: Efficient models lower energy consumption through better controls and motors, leading to significant reductions in operational expenses over time.