Reliable Variable Frequency Screw Air Compressors for Construction Machinery Power Supply

News 2025-10-31

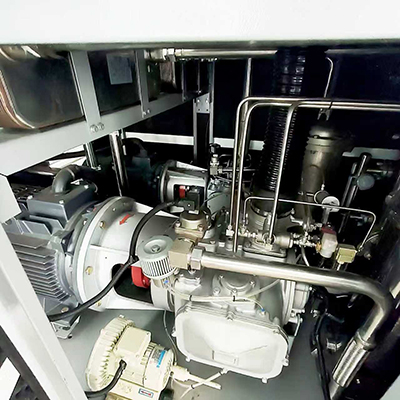

Variable frequency screw air compressors play a critical role in powering construction machinery by delivering consistent and adaptable air supply. These systems adjust output based on real-time demand, enhancing efficiency in dynamic environments like building sites. They ensure machinery operates smoothly, reducing energy use and supporting heavy-duty tasks such as excavation and material handling. By integrating advanced technology, these compressors meet the rigorous needs of modern construction, promoting both performance and sustainability.

Application Scenarios

In various construction settings, these compressors power essential tools and equipment. For instance, they drive pneumatic drills and hammers in tunneling projects, provide air for sandblasting in surface preparation, and support lifting mechanisms in crane operations. Their portability makes them ideal for remote sites, where they can be mounted on vehicles or used in temporary setups, ensuring uninterrupted workflow even in challenging conditions.

Performance Advantages

The variable frequency design offers superior control and efficiency, allowing compressors to ramp up or down based on load, which minimizes energy waste. This results in quieter operation and extended equipment life, as reduced stress on components lowers maintenance needs. Compared to traditional models, they deliver higher air flow rates with less power, making them cost-effective for long-term use in construction, where reliability under varying conditions is key.

Importance in Industrial Processes

Reliable air compression is fundamental to industrial efficiency, preventing delays caused by power inconsistencies. In construction, these compressors maintain steady pressure for safety-critical applications, such as operating brakes and controls in heavy machinery. Their role in reducing emissions and operational costs supports sustainable practices, ultimately contributing to project timelines and budget adherence in an industry focused on precision and durability.

Frequently Asked Questions

1. What is a variable frequency screw air compressor?

A device that uses inverter technology to adjust motor speed and air output, optimizing performance for specific needs.

2. How does it benefit construction machinery?

It provides energy-efficient power supply, reduces wear on equipment, and ensures consistent operation in fluctuating conditions.

3. What factors affect its reliability?

Factors include proper installation, regular maintenance, and selecting models suited to environmental demands like dust and temperature.