Professional Variable Frequency Screw Air Compressors for Packaging Machinery Support

News 2025-10-31

In the fast-paced world of packaging machinery, reliable air compression is crucial for maintaining efficiency and precision. Variable frequency screw air compressors offer advanced solutions by adjusting motor speed to match demand, reducing energy waste and enhancing operational stability. These compressors are engineered for durability and performance, making them ideal for industries where consistent air pressure is essential for tasks like sealing, filling, and labeling. By integrating variable frequency technology, packaging operations can achieve smoother workflows and lower maintenance costs, supporting the high-throughput demands of modern production lines.

Application Scenarios

Variable frequency screw air compressors excel in diverse packaging applications, such as food and beverage processing, pharmaceutical packaging, and consumer goods assembly. In bottling lines, they provide precise air flow control to handle varying production speeds, ensuring bottles are filled and capped without errors. For flexible packaging, these compressors adapt to changes in machinery load, supporting automated systems that wrap, seal, and label products efficiently. Their ability to operate in harsh environments, like high-humidity or dust-filled settings, makes them a preferred choice for enhancing reliability in packaging facilities worldwide.

Performance Advantages

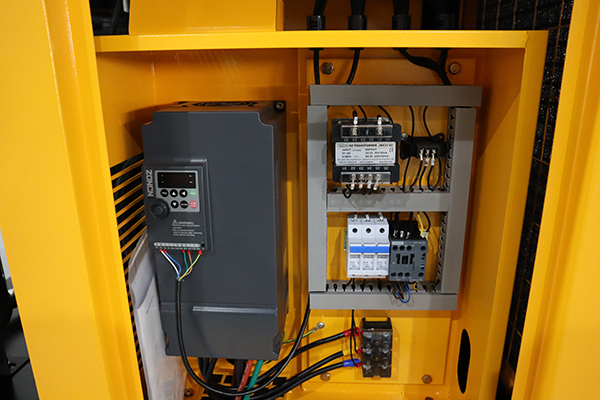

These compressors deliver superior energy efficiency through variable frequency drives, which optimize power consumption by matching output to real-time needs, potentially cutting energy bills by up to 30%. Their screw design ensures oil-free or low-oil operation, minimizing contamination risks in sensitive packaging processes. Additionally, built-in monitoring systems provide real-time data on pressure, temperature, and usage, allowing for predictive maintenance that reduces downtime. With quiet operation and compact footprints, they integrate seamlessly into existing machinery setups, boosting overall system performance and longevity in demanding industrial environments.

Importance in Industrial Processes

In industrial settings, variable frequency screw air compressors play a pivotal role in streamlining operations by ensuring consistent air supply critical for automation and control systems. They contribute to sustainability efforts by lowering carbon footprints through reduced energy use, aligning with global efficiency standards. By enabling precise pressure regulation, they support complex processes like high-speed sorting and robotic handling, where any fluctuation could lead to product defects or safety issues. Ultimately, their integration enhances productivity, cost-effectiveness, and competitiveness in the packaging sector, driving innovation in manufacturing workflows.

Frequently Asked Questions

1. What is a variable frequency screw air compressor?

It is a type of air compressor that uses a screw mechanism and variable frequency drive to adjust speed and output based on demand, improving efficiency.

2. How does it support packaging machinery?

It provides stable, adjustable air pressure that matches machinery requirements, reducing energy consumption and preventing operational disruptions in packaging lines.

3. What are the main benefits for industrial use?

Key benefits include energy savings, reduced maintenance, and enhanced control, which improve overall productivity and reliability in industrial processes.