Durable water-lubricated oil-free screw air compressor long service life

News 2025-11-17

Durable water-lubricated oil-free screw air compressor long service life

Clean compression technology for modern industries

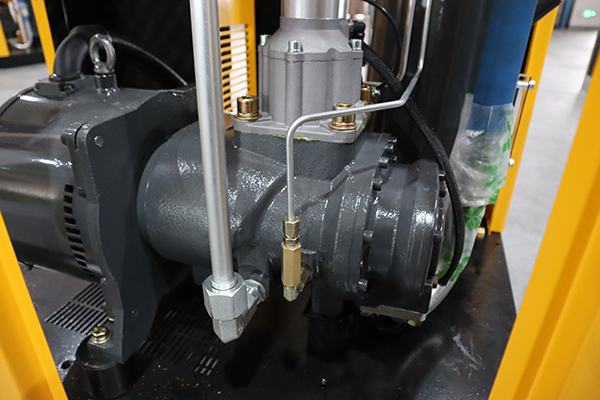

A durable water-lubricated oil-free screw air compressor is designed to deliver clean, high-quality compressed air while eliminating mineral oil from the compression chamber. Using treated water as the sealing and cooling medium, it minimizes contamination risk, supports strict air purity classes, and simplifies downstream filtration. This technology is particularly valued in industries such as food and beverage, pharmaceuticals, electronics, medical devices, and precision coating, where oil carryover would compromise product quality or safety. By integrating robust screw elements, intelligent control systems, and corrosion-resistant materials, the compressor maintains consistent performance under long operating cycles and demanding industrial environments.

Key performance advantages and energy efficiency

Compared to traditional oil-injected systems, the water-lubricated oil-free screw compressor offers several performance advantages. Water has excellent thermal capacity and heat transfer characteristics, enabling lower discharge temperatures and stable isothermal compression. This improves volumetric efficiency, reduces mechanical stress, and extends the service life of bearings and seals. Variable speed drive options further optimize power consumption by matching air supply to real-time demand, lowering energy costs in continuous-duty applications. In addition, the oil-free design reduces pressure drops in filters and dryers, resulting in better system efficiency and lower total cost of ownership over the full life cycle.

Critical role in sensitive industrial processes

In many process-critical applications, the quality of compressed air directly affects product integrity and regulatory compliance. Water-lubricated oil-free screw air compressors help manufacturers meet stringent standards such as ISO 8573 air quality classes, GMP requirements, and cleanroom specifications. In pharmaceutical production, they protect against contamination of tablets, injectables, and inhalation drugs. In food processing and packaging, they prevent oil aerosols from contacting ingredients, finished goods, and contact surfaces. For electronics and semiconductor operations, ultra-clean air protects delicate circuits, sensors, and coatings from particle and oil-related defects, improving yield and reducing rework costs.

Application scenarios, service life, and maintenance

These compressors are well suited to 24/7 industrial operation in large manufacturing plants, central utility stations, and multi-line production facilities. Long service life is achieved through optimized screw rotor profiles, advanced surface treatments, stainless steel components in wet sections, and precise water quality management. Intelligent controllers monitor temperature, pressure, flow, and water condition, issuing alarms before abnormal wear occurs. Routine maintenance focuses on periodic water replacement, filter inspection, and system cleaning, rather than frequent oil changes and disposal. This reduces environmental impact, simplifies compliance, and keeps uptime high, making the compressor an attractive choice for companies prioritizing sustainable, low-risk compressed air supply.

1、What industries benefit most?

Water-lubricated oil-free screw air compressors are ideal for food and beverage, pharmaceutical, chemical, electronics manufacturing, medical, textile, and high-purity coating applications where even trace oil contamination is unacceptable.

2、How does it reduce operating costs?

By eliminating oil, reducing filter pressure losses, and using efficient cooling, the system lowers energy consumption, cuts lubricant-related expenses, and extends maintenance intervals, providing a lower total cost of ownership over its long service life.

3、Why is water lubrication important for air quality?

Water lubrication separates the compression process from mineral oils, minimizing oil aerosols in the air stream. This helps meet stringent air purity standards, protecting sensitive products, equipment, and end users throughout the entire industrial process.