Affordable water-lubricated oil-free screw air compressor budget-friendly option

News 2025-11-17

Affordable water-lubricated oil-free screw air compressor budget-friendly option

Clean air solution for sensitive industries

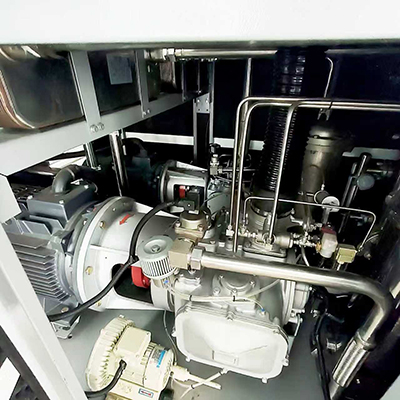

Water-lubricated oil-free screw air compressors deliver high-quality compressed air while removing the risk of oil contamination. They are widely used in food and beverage processing, pharmaceutical production, electronics assembly, laboratory facilities, and medical devices manufacturing, where even trace oil vapors can compromise product integrity or regulatory compliance. By using water as the sealing and cooling medium, these compressors provide ISO-class clean air suitable for direct contact applications, supporting HACCP, GMP, and other industry standards while maintaining a budget-friendly total cost of ownership.

Key performance advantages and energy efficiency

Compared with traditional oil-injected screw compressors plus downstream filtration, water-lubricated oil-free models simplify the air treatment chain and reduce pressure loss, improving overall system efficiency. Their screw airend is cooled uniformly by water, delivering stable discharge temperatures and consistent pressure, which reduces thermal stress and extends component life. Variable speed drive options allow precise matching of airflow to fluctuating demand, minimizing unload losses and cutting energy consumption in continuous or multi-shift industrial environments, making them a cost-effective choice over the equipment lifecycle.

Application scenarios across modern industrial processes

In bottling plants and breweries, oil-free screw air supplies process air for rinsing, filling, capping, and conveying, ensuring that compressed air contacting product or packaging remains uncontaminated. In pharmaceutical and biotech facilities, it drives pneumatic valves, blister packing, lyophilization support systems, and cleanroom utilities, where air purity directly affects drug safety. Electronics and semiconductor workshops rely on dry, oil-free air for pick-and-place robots, precision tools, and cleanroom pressurization, preventing surface defects and corrosion. Even general manufacturing, such as automotive, textiles, and plastics, benefits from reduced filter maintenance, fewer product rejects, and improved brand reputation.

Maintenance, cost control, and environmental benefits

Water-lubricated oil-free screw air compressors typically require fewer consumables, since there is no oil to replace and fewer high-load filtration stages. Maintenance staff focus mainly on water quality management, routine inspections, and standard wear parts, which keeps downtime predictable and manageable. Eliminating lubricating oil also simplifies condensate treatment and reduces hazardous waste, supporting corporate sustainability goals and helping companies meet stricter environmental regulations. Over time, lower energy use, reduced filter replacement, and minimized product contamination risks combine to make these systems an attractive, budget-conscious investment for factories upgrading their compressed air infrastructure.

Common questions about water-lubricated oil-free screw air compressors

1. What industries benefit most?

Applications in food, beverage, pharmaceuticals, electronics, medical devices, and any process where compressed air can contact the product gain the greatest value from oil-free screw technology.

2. How do they save energy?

By using efficient screw elements, optimized cooling, and optional variable speed drives, these compressors cut pressure losses and reduce unload time, lowering kWh per cubic meter of air.

3. Are they difficult to maintain?

They are generally straightforward to maintain; the focus is on monitoring water quality, routine inspections, and scheduled replacement of basic components rather than handling complex oil management systems.