Rotary Screw Air Compressor Brands for Heavy Duty Use

News 2025-10-24

Rotary screw air compressors are a vital component in heavy-duty industrial operations, delivering reliable and efficient compressed air for demanding tasks. Their design, featuring interlocking screws that compress air continuously, ensures a steady output without pulsations, making them superior for applications requiring consistent pressure. In environments like manufacturing facilities and construction sites, these compressors handle high workloads, reducing downtime and enhancing productivity through their robust engineering and energy-efficient performance.

Leading Brands in the Market

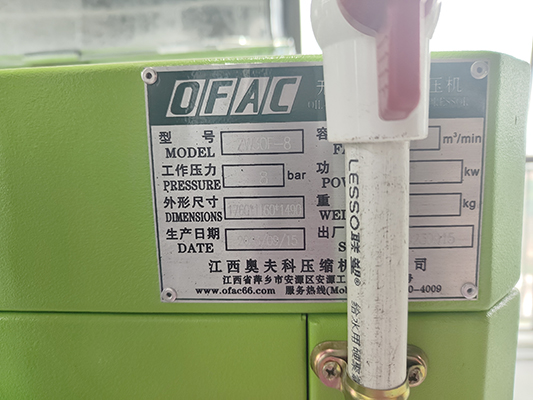

Key players in the rotary screw air compressor industry include Atlas Copco, known for its durable models with advanced cooling systems that maintain performance under extreme conditions. Ingersoll Rand offers compressors with intelligent controls for optimized energy use, while Kaeser provides high-efficiency airends that minimize wear in heavy-duty scenarios. Sullair stands out with portable, rugged designs ideal for field operations, ensuring brands meet diverse needs with features like variable speed drives and low-noise operation.

Performance Benefits for Heavy Applications

These compressors excel in heavy-duty use due to their high flow rates and pressure capabilities, which support uninterrupted operation in intense settings. Their efficiency reduces energy consumption, leading to cost savings and lower environmental impact, while durable components resist corrosion and heat, extending equipment lifespan. Additionally, features like oil-free options prevent contamination, making them suitable for sensitive processes and contributing to safer, more reliable industrial workflows.

Core Application Scenarios

In manufacturing, rotary screw compressors power pneumatic tools and automation, boosting output in assembly lines. For construction, they drive equipment like drills and pumps on job sites, while in mining, they facilitate ventilation and material handling under harsh conditions. Other sectors, such as automotive and food processing, rely on them for tasks like painting and packaging, where consistent air supply is critical for efficiency and quality control.

Role in Industrial Efficiency

Rotary screw air compressors play a pivotal role in industrial processes by ensuring seamless integration with machinery, which minimizes disruptions and supports high productivity. Choosing the right brand enhances system reliability, helping industries meet tight deadlines and regulatory standards. Their contribution to energy savings and reduced emissions also aligns with sustainable practices, making them indispensable for modern operations that prioritize both performance and environmental responsibility.